The following information on Smith & Wesson revolver accuracy comes from of Burning Powder by Lt. Col. Douglas B. Wesson. Burning Powder is also available to purchase in print.

For many years it has been realized that the .22 Single Shot pistol has all the inherent accuracy of the rifle, but it was generally assumed that the revolver, with its problem of barrel and cylinder alignment, to say nothing of the fact that there was obliged to be, by the design of the arm, some jump of the bullet when leaving the chamber and entering the barrel, had only what might be called comparative accuracy; in fact so strongly was this belief held that even today it is not uncommon to hear some shooter state in all seriousness that one revolver is more accurate than another, basing his opinion on the fact that he, shooting offhand, scored better with that arm.

It is an unfortunate fact that with the ordinary run of revolvers the criticisms mentioned above may well be warranted; it is only in the highest type of arms that the design and precision of manufacture are such that actual accuracy can be consistently secured and maintained. Furthermore, the problem of the design of a suitable machine rest for testing revolvers was one that was only solved by ourselves within the past few years; until then the machine rests in use, even those in the ballistic departments of the large ammunition companies, were utterly incapable of giving results even approximating the capabilities of the revolvers and ammunition. Without doubt the results obtained from these inferior machine rests contributed to the general feeling that mere casual accuracy could be expected from a revolver.

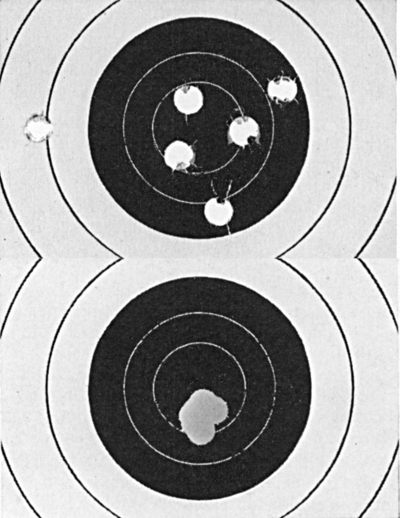

Some years ago while developing the K-.22 revolver, we designed and built a machine rest on a unique principle that proved highly successful, and we were enabled, for the first time in the history of revolver manufacturing, to demonstrate the actual accuracy of our arms. We produced, in fact, such close groups with the K-.22 that when they were first published their authenticity was publicly questioned by certain “authorities.” One of these .22 caliber groups is shown here; made at 60 feet with the Smith & Wesson rest, six shots, one from each chamber. We also show a target made with a S&W .357 Magnum. It might be well to say at this point that the same barrels, cylinders, chambering, rifling and reaming that are used in our target arms are found in our service arms, and the accuracy of the two types of arms is identical.

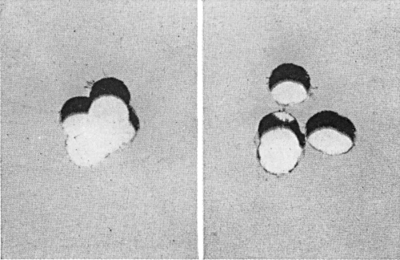

The advent of a dependable machine rest brought to light many interesting points that heretofore had been suspected but proof for which was lacking. A very good example is the flat nose, or wad cutter bullet; this bullet, particularly in the .38 S&W Special Mid-Range load, is by far the most popular among the target shooters in the large caliber matches. With this bullet we frequently encounter definite indications of “Bullet tipping,” the hole in the target will be slightly oval instead of perfectly round, and one side of the oval will show lead marking. This is to be in no way confused with “keyholing,” as in this case the hole in the target will show the bullet was travelling much more sideways, in fact, it may indicate that the bullet was travelling actually sideways as it passed through the paper; when we encounter keyholing the bullet is actually tumbling through the air. With the machine rest we are able to prove by shooting and examining the resulting groups, that the tipping of the wad cutter bullets does not affect the accuracy in the slightest. The six shots showing bullet tipping were fired from the same arm, using ammunition from the same box that produced the machine rest group shown on preceding page.

With the machine rest we have demonstrated by actual test the fact that with proper alignment of the barrel and cylinder of a revolver, the distance that the bullet has to jump after leaving the shell and before entering the barrel, has, within reasonable limits of jump, no effect whatsoever on the accuracy of the arm. This accounts for the fact that with our K-.22 revolver we can make at 30 feet most excellent machine rest groups using the tiny CB caps, and with .38 S&W Special Mid-Range Wad cutter ammunition in our .357 Magnum at 60 feet we will secure six-shot groups that can be more than covered with a dime.

We are now convinced that the length of a revolver barrel has no bearing on the accuracy of the arm; any barrel that is sufficiently long to impart a true spin to the bullet is fully as accurate as a longer one. The longer sighting base of the longer barrel may be of assistance to the shooter in his holding, but from the standpoint of the accuracy of the arm it has no bearing.

At short ranges of say, twelve or fifteen feet one will at times notice on a target signs of bullet tipping, particularly with the .22 Long Rifle; this is due to gyroscopic effect, the bullet travelling a straight path with its nose, but the base not having settled down in its spin, is describing circles around the line of flight. A good example of this action is the movement of the upper part of a top when it is first started spinning and before it “goes to sleep.”

It goes without saying that the accuracy of a revolver is dependent to a great extent on the ammunition that is used in it, but it was not until a dependable machine rest was developed that we were enabled to give definite and accurate examples of the tremendous variations that are encountered in different commercial loadings.

Another point that affects the accuracy of any arm to a surprising extent is the weight of hammer nose or firing pin blow on the primer; this is entirely overlooked by many who attempt to ease the action of their revolvers or reduce the trigger pull by weakening the main spring or relieving the tension by backing out the strain screw. The fact that the hammer blow is sufficient to ignite the primer is no indication that the blow has the proper weight for uniform ignition, even though there may be no misfires; there is bound to exist in primers a variation in sensitiveness and the hammer blow must be such that it will produce complete ignition in all cases. The targets shown here indicate plainly the results of lack of uniform ignition; the first group was made with the mainspring at the proper tension, the second, with the main spring slacked off to obtain a lighter blow, but not to the extent of producing misfires. The groups shown were fired in the order shown, using a Magnum in the machine rest, and the 12 cartridges were from the same box, and under identical conditions, but for the fact that the mainspring tension screw was backed out several turns, thus lightening the hammer blow on the primer. The most casual study of the illustrations can but impress one with the necessity of the selection of the proper weight of blow if one is attempting to obtain the utmost in accuracy.

There is one condition that we have found to exist that, frankly, we are unable to account for; we can only admit its existence, and that is what we describe as “selectivity.” “Selectivity” is the word used to attempt to describe the condition where two revolvers as nearly identical as it is humanly possible to make them, show marked preference for two different makes or brands of ammunition; in other words, where revolver “A” will, in a machine rest, produce closest groups with ammunition “X,” while revolver “B” performs to the best advantage with the “Y” cartridge. This is an acknowledged condition in all firearms, but shows up most clearly in the .22 caliber revolvers and rifles.

Click here to purchase Burning Powder in paperback

Return to Burning Powder Table of Contents