The following information on hotbeds and cold frames comes from Five Acres and Independence by M. G. Kains. Five Acres and Independence is also available to purchase in print.

In no one direction has interest in gardening been so characterized as in the increasing numbers of cold frames and hotbeds employed by amateurs as well as commercial men. Under modern construction, these adjuncts have many striking advantages among which the following are sure to make appeal.

By means of hotbeds (Fig. 28) plants of desired flower and vegetable varieties may be started weeks or even months before they could be sown outdoors. Instead of relying upon other sources for supplies of seedlings or potted plants, one’s own seed may be started in the hotbed, pricked-out in cold frames, inured to the weather (“hardened off”) and when outdoor conditions are favorable, transplanted to the garden.

By starting hardy perennials and biennials several weeks before outdoor sowing would be safe the plants may often be made to bloom during the first season instead of having to wait until the second year. Similarly cuttings of many perennials, roses, and other flowering subjects may be started in a hotbed and advanced by the same stages to the open ground.

The cold frame alone may likewise be used for slower-rooting varieties. One great advantage of this practice is that you may propagate a personal stock of favorite plants and thus be sure that the young ones are true to name.

With a hotbed or a cold frame the difficulties and disappointments often incident to starting minute seeded plants may be wholly avoided; for when a shower threatens the beds may be protected by sash and the danger of washing out or burying either the seeds or the seedlings in mud obviated.

Risks of starting tender subjects too early or too late outdoors may be avoided. When seed of such varieties is sown too early in the open the weather may be so cold and wet it may decay or the seedlings be nipped by a tardy spring frost; when too late, the plants may meet unfavorable summer conditions, develop poorly and perhaps be destroyed by an autumn frost before they have reached desired development. This is of special application to growing cantaloupes, cucumbers and watermelons, though it also includes other tender plants such as tomato, eggplant, pepper, dahlia, canna and geranium.

In localities where blight destroys watermelons, cantaloupes and cucumbers, hotbeds and cold frames also enable the gardener to avoid this disease or to ward off its effects until after the fruits have been ripened; for by starting the plants on inverted sods, in flower pots or other convenient receptacles to favor transplanting they may be kept in the frames and readily sprayed, dusted or fumigated to kill cucumber beetles and squash bugs which not only feed on them but spread blight infection from plant to plant.

Even when not growing plants, cold frames are admirable for extending the ripening season of tomatoes that would otherwise be spoiled by an early fall frost. The fruits that show pink may be gathered when falling temperature threatens damage, placed on deep layers of straw in the frames and covered with sash whenever the weather is wet or cold. The rate of ripening may be accelerated to a week or so by keeping the sash on the frames during the day, thus raising the temperature; or it may be delayed by leaving them off whenever the weather will permit without risk of frost-bite. Thus the tomato season may be extended to Thanksgiving Day or even later. The frames may also be used to store such late vegetables as celery, endive, cauliflower, Brussels sprouts and witloof chicory (so-called “French endive”) and for carrying semi-hardy plants such as chrysanthemums over winter.

In spite of such an array of advantages, many people hesitate to have either a hotbed or a cold frame for fear their lack of experience or their conditions may induce failure. Yet faced with both inexperience and lack of ideal conditions, thousands of novices have plunged and succeeded beyond their most sanguine hopes. Of course, the nearer you can approach ideal conditions the more likely are you to succeed. These are a southern exposure (or next best a southeastern) and protection from high winds, especially from the north and the west, by a windbreak such as woods, tall hedges, or buildings.

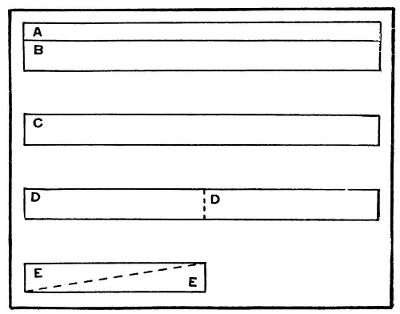

Modern, standard, commercial (3′ x 6′) sash and (6′ x 12′) hotbed frames (Fig. 28) are made so accurately and of such desirable materials (cypress or redwood), are so easy to duplicate and cost so little that they should always be preferred to homemade ones. The 6′ x 12′ frame is especially desirable to start with because it is more convenient to operate (having a larger volume of air) than a smaller one. If desired it may be divided by a partition across the middle so half may be used as a cold frame and the other as a hotbed. Being assembled by bolts and angle irons it may be readily taken apart and stored flat or on end in small space or moved from one property to another, thus appealing to renters. While “knocked down” it may be easily cleaned and painted and thus made to last for many years.

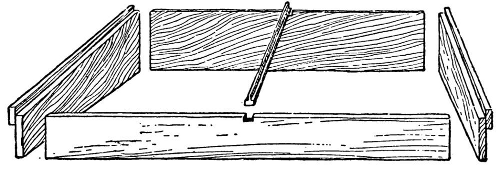

For a cold frame no excavation is usually made; for a hotbed the area to be excavated should be at least 6″ wider and longer than the frame so there may be plenty of space for the foundation. This may be made of stone, brick, concrete or 2″ planks, preferably of “pecky” cypress, when such are available; otherwise clear cypress or some other wood that resists decay—locust, cedar, chestnut. The foundation should extend a few inches above the surface to increase the longevity of the frame itself. A post is at each corner and at 4′ intervals on the sides of all wooden foundation frames.

The depth of excavation will depend upon the climate; it varies with the local frost line. From Maine to Minnesota and northward 24″ to 30″ is favored; in southeastern New York, 18″ to 24″; near Washington, 12″. In the South the frame usually rests directly on the ground without excavation or foundation frame.

Though all commercial sash are 3′ x 6′, users have preferences and objections to various types. Some prefer lightweight styles because easier to handle than heavy ones; others, the reverse because the frame, being sturdier, they claim glass breakage is less. For this same reason many growers prefer sash with four rows of panes rather than three. But, others point out, the three-row style casts less shadow.

Double glass sash have both proponents and opponents, the former claiming protection equivalent to straw mats placed upon single glass sash, thus avoiding the work of laying and removing the mats (real work when wet or icy), giving the plants full sunlight and therefore better growing conditions than under single glass sash.

Opponents object to the greater weight of double glass sash, the 25% to 30% extra cost, the retention of moisture between the upper and the lower glass and consequently the encouragement of decay. They also declare that the accumulation of dirt between the panes results in shade and poorer growth of plants, and that all the advantages of double glass may be gained without any of the disadvantages by placing a second single glass sash on top of the first during cold weather. In any case it is advisable in northern localities to have protective mats (straw, burlap, felt or other material) and often matched board shutters to place over the sash when the weather is inclement, especially when windy.

The only difference between a cold frame and a hotbed is that heat in the former all comes from the sun. Hotbeds may be heated in several different ways. Fermenting material, especially fresh horse manure, though formerly popular is objectionable because of its present day scarcity, high cost, labor to prepare, short period of usefulness, fumes of fermentation (especially of ammonia), and the excess of attention as to ventilation that beds so heated require. It is inferior to all other means of heating hotbeds.

During the past few years electricity as a source of heat has been gaining rapidly in popularity because of its advantages over all other methods. Where electric current is available only an “outlet” is needed—such as used for the toaster. As proved by experiment stations (especially New York, Oregon, Minnesota, and Missouri), by various organizations as well as by electrical apparatus manufacturers (whose bulletins and advertising matter are available at little or no cost) the electric hotbed is free from all the objections to fermenting materials and is superior to steam and hot water. Among advantages thus determined the following are outstanding:

Electricity costs less to operate than do steam and hot water (approximately 50 kilowatt-hours to the sash during the growing season). It has probably longer life than either. When properly installed with thermostatic control it is safe and easy to operate, produces uniform heat at any desired temperature, demands a minimum of attention and eliminates the difficulty and work of preparing manure.

For temporary (especially rented properties) its convenience, adaptability, and portability make special appeal.

A cold frame may be converted into a hotbed or vice versa by merely turning a switch on or off. This saves time in starting seedlings because, regardless of weather conditions seeds may be sown later, seedlings grown faster and, thanks to the thermostat, sturdier plants may be produced than by any other system applicable to frames.

Electricity is clean and agreeable to work with and is always ready to use. As it may be turned on immediately after installation it saves loss of time incident to the use of manure whose heat must always be allowed to subside to less than 90º F. before seeds may be sown with safety. It is an economical substitute for manure when the cost of hauling and handling are included.

A hotbed 6′ x 12′ may be permanently electrified for about $5; a manure bed must be made and the manure paid for fresh every year. Whereas an electrified bed may be heated every day in the year, one can be warmed by manure during only 6 to 8 weeks. When current is shut off a hotbed becomes a cold frame, so no extra cold frames are needed for hardening-off plants. Thus the work of shifting plants from one to the other may be avoided. Cold frames may be kept from freezing by hanging electric cables around the inside walls and turning on the current when needed.

Anybody can install an electrical heating system by attaching the heating “elements” and the thermostat as shown in Figure 29 and plugging into an outlet connected with the house wiring system. Regulation of the heat is done automatically by the thermostat which may be set to operate (shut off and re-connect) the current at any desired temperature. At the close of the season the system may be disconnected and stored along with the sash and the frames until the following spring.

Without going into detail it may be said that one amateur grew about 5,000 plants of 50 flower and vegetable varieties at an operating cost of only $1.60 for current (the rate being 10 1/2c a kilowatt hour). The bed was equipped with wires, eight 25-watt vacuum bulbs and a thermostat for only $5 and half a day’s time to install. The thermostat, set to operate at 50º F., maintained a temperature within “safe limits during sub-freezing weather,” part of the time 16º F. above zero.

Hotbed heating by electricity is also done through thermal cables, either strung around the walls, laid near, upon or beneath the soil surface, or as plates placed beneath separate flats. Though styles of apparatus and application vary widely and are annually being improved, all are more satisfactory than manure, steam and hot water methods. Electricity has also proved advantageous for heating propagation benches and for forcing such vegetables as lettuce, tomatoes and cucumbers. In short, its convenience, economy, cleanliness and automatic control are what so strongly appeal to gardeners both amateur and professional, and account for its rapidly increasing popularity.

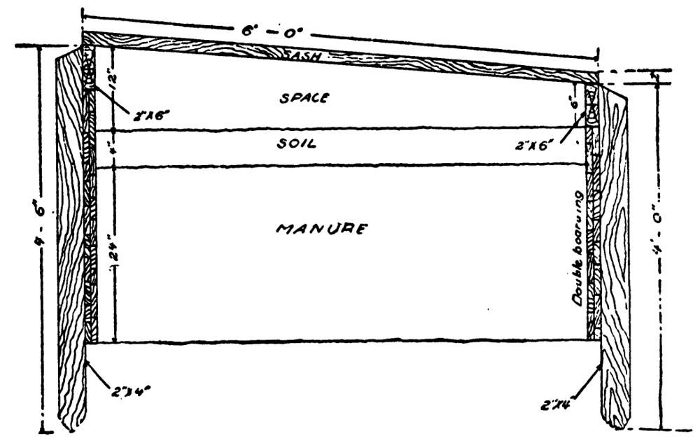

Various methods of applying the heat have been tried in several states but, so far as I know, not more than two had been compared until T. M. Currence conducted experiments with the four types illustrated in Figure 29 and detailed his findings in Bulletin 239 of the Minnesota Experiment Station. Among his conclusions the following have special significance to the man who wants to use electricity for heating his hotbeds or converting his cold frames into hotbeds. They are also of particular value because of the rigorous climate of the locality in which the work was done. This is far stronger proof that electricity is safe to install where cold weather is the rule than if the tests had been made farther south where the winters and springs are less severe.

For these experiments the hotbeds were built of 1″ pine boards entirely above ground on a southern exposure and upon gravelly soil; they were lined with insulating material, covered with a waterproofing compound, the outside with roofing paper; in cold weather they were protected by 1/2″ felt mats. All were equipped with meters and thermostats to measure the current and regulate the temperature, respectively.

Frame A was heated and lighted by four 100-watt Mazda lamps attached to a 1/2″ pipe crosspiece about 12″ above the soil; each lamp had a 6″ shallow cone reflector. In Frame B, 120′ of hotbed cable was placed in the soil to deliver 200 watts of heat and had 4 50-watt Mazda lamps suspended as in Frame A. In Frame C, 60′ of cable was placed 6″ below the soil surface to deliver about 400 watts of heat, and a supplementary 60′ as a precaution to produce additional heat when necessary—though the occasion did not arise. In Frame D, 60′ of cable was hung on the inside walls.

Efforts were made to adjust the thermostats so they would operate in a range of 50 to 55º F. but sunshine and the difficulty of making them operate at the same temperature caused—not serious—variations of the heat. During four weeks of winter weather the differences in current cost were not great.

The largest crops were grown in Frame A. doubtless because of the stimulating effect of the light. The temperature in that frame averaged more than 3º lower than in any of the others. Once when the temperature fell to 15º below zero the lowest temperature in any of the frames was 38º above zero. This indicates that when reasonable care is exercised in frame construction and the use of mat protectors, each method of applying current will protect plants from freezing. Frame D, with coil above ground, used least current in the winter test and produced better plants than did Frame C. Frame A produced somewhat uneven, rank growth. The unevenness could probably be prevented by better distribution of the lights. Combination of bottom and overhead heat was costly to operate but the plants made good growth. Much difficulty was found in regulating moisture in Frame C. When ventilation in this frame was reduced to a minimum in cold weather, moisture condensed on the glass and tended to keep the soil surface wet, and when properly ventilated the soil dried out rapidly, baked and current was wasted. Perhaps unfavorable moisture conditions accounted for poor growth of plants in this frame.

Each method has advantages and disadvantages for commercial use. Apparently bottom heat should be least costly for seed germination; lights most desirable for rapid growth, especially in cloudy weather; combination of these two will supply widest range of adaptability; possibly best results might be obtained by using bottom heat to germinate seeds, and lights after the seedlings appear; 25-watt lamps, 4 to a sash, give good distribution of light and tend to eliminate uneven growth.

Lights would be desirable for beds smaller than 6′ x 6′. To reduce the watts of heat necessitates lengthening the heating cable. Heating capacity of 200 watts would require 120′ of cable, a length cumbersome to install in small area.

Commercial trials in Minnesota summarized in the same bulletin, supplement the findings in the above experiments by the statements that electricity makes a saving of 2 weeks over manure heated hotbeds; current used during the first month was 30 kilowatt-hours a sash; at 3c a kilowatt-hour (the local rate) the cost was 90c a sash in 2 cases (the third not comparable); all 3 growers plan to increase the number of their electric hotbeds—a sure sign that they recognize the advantages of electric hotbed heating.