The following information on farm water drainage ditches comes from Five Acres and Independence by M. G. Kains. Five Acres and Independence is also available to purchase in print.

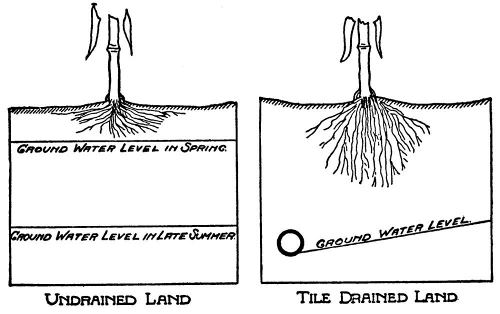

Unless soil is well drained there is no use trying to produce profitable crops. Yet it is astounding how many farmers and fruit growers and even truck farmers try to make a living off such soils. Undrained lands are not merely wet but cold and often acid. Because of the wetness they cannot be worked nearly as early in spring as well drained lands; when seed is sown it germinates poorly, unevenly or not at all; such plants as start develop roots near the surface and when summer comes they suffer because they cannot then reach water which by that time is at a much lower level. Crops are therefore late, poor and unprofitable.

Where land is not naturally well drained, artificial drainage is a necessity. It is often the one factor that makes all the difference between bankruptcy and profit.* From a financial standpoint, underdrainage can be considered as a long-time investment. Tile drainage of agricultural lands is a comparatively expensive improvement and the capital expended in drainage work cannot be recalled or transferred, but owing to its permanent nature a properly installed drainage system should continue to return dividends for many years. Just how many is problematical, but in a general way tile drains may be said to last a lifetime. Underdrainage, like most other long-time investments, will often pay dividends sufficient to return the original capital in two or three years. [*From this point forward parts of what follows in this chapter are condensed from Bulletin 360, by F. L. Ferguson, Director of Drainage, of the Ontario Department of Agricultural Engineering.]

All soils not naturally drained require drainage. These usually are cultivated areas with fair surface drainage but with heavy subsoil; heavy clay soils with little or no surface drainage; rolling areas with impervious subsoil; areas, large and small, saturated long enough each year to destroy the physical condition of the soil and to interfere with spring seeding and harvesting operations; pot-holes and swamp areas.

Drainage benefits crops by permitting earlier spring seeding; making the land more easily worked; encouraging higher percentage of seed germination; making the soil more favorable to root development, hence providing more moisture and plant food (Fig. 18); reducing winter killing; controlling weeds more easily; and by increasing crop yields.

Whether the area to be drained is large or small, whether one drain or many may be needed, it is generally advisable to have the area surveyed and a plan drawn to scale. Such a plan will show the proper locations for all mains, submains, laterals and silt basins; the number and size of tile for each drain; the possible grades and depths; the best possible outlet or outlets and the locations of obstructions, buildings, trees, fences, etc.

With this information the farmer will be in a position to put in as much as his time, help or financial conditions will permit. The main drains should be installed first and the others added at will. Further, he may call for bids on a contract and have a basis upon which to calculate the cost of the system. Since the same area often lends itself to several different drainage schemes, the most economical may be chosen.

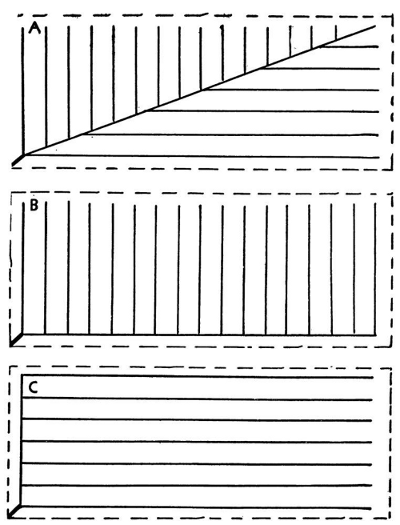

Figure 17 shows three methods of draining the same 10-acre field in which it is assumed that the slope of the land is equally favorable to each system and under each will be equally well drained. However, as figured out Plan A (herring bone system) costs $45.98 an acre; Plan B $42.59 and Plan C $41.65. Moreover, Plan B is more difficult for the machine operator to install because of the number of short drains. A study of these plans shows the advantage of having a drainage survey made by a competent engineer, whose duty it is to install the most efficient and economical system possible.

The cost of drainage work varies, first, with the system required—in some cases a “system” is necessary, in others merely a few drains; second, the nature of the crops to be grown; third, the kind of digging; fourth, the location of the tile plant; and fifth, whether or not power machinery is available.

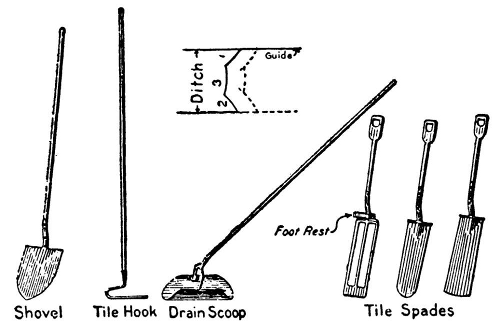

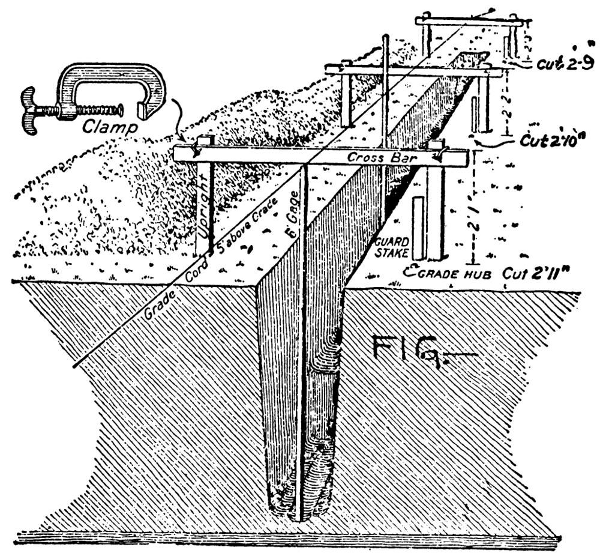

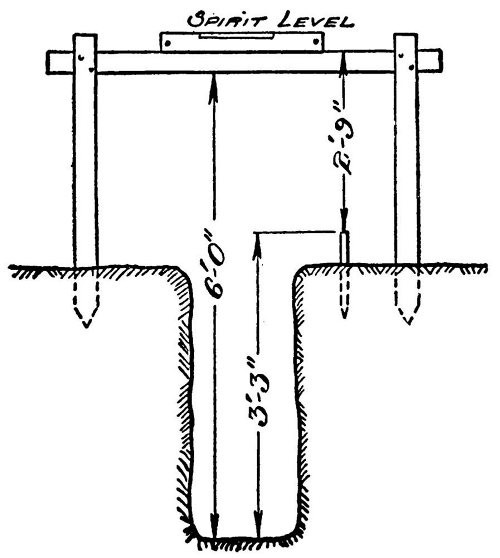

Tile may be installed either by hand or by a ditching machine. The latter, when properly operated, is quicker, more efficient and usually more economical. When hand work is necessary, one can make use of an ordinary plow, a ditcher, a ditching machine, or other digging machinery now on the market. In any case the following points should be kept in mind:

The grade must be uniform so there will be no depressions to collect sediment; a solid bottom is essential—tile laid on muck or other soft material is likely to shift out of alignment and to obstruct the flow of water; stones and other obstructions encountered in the trench must be removed, the holes being carefully filled and tamped to give a solid bottom; only the best tile should be used; blinding and back-filling must be carefully done to prevent the breakage of tile by rolling stones or by horses stepping in the trench; junctions and outlets must be carefully constructed; and trees likely to block the tile with their roots must be removed.

Ordinarily, tile should be laid as closely together as the cut ends will permit. In heavy clay soils a little opening is not objectionable, but in sands or sandy loams it is necessary to fit them closely together. In the latter it is often desirable to cover the upper half of the tile with tar paper to prevent the sand from entering. Whether tile are laid by hand or with a hook is not important so long as they are kept in proper alignment and well graded. Junctions should be carefully constructed in order that no obstruction may offer resistance to the flow of water. A few inches of soil, preferably the surface soil, should be placed over the tile as soon as they are laid to make sure they will not shift by accident. Back-filling should be done as early as possible because soil often becomes baked after rain or in other ways is hard to move.

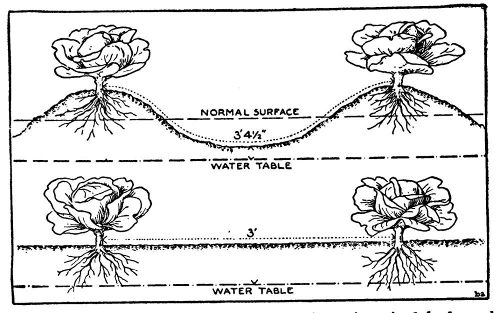

Depths and distances apart of drains depend almost entirely upon the nature of the soil. The lighter the soil the deeper and farther apart; in heavy soil they must be placed closer together and somewhat shallower.

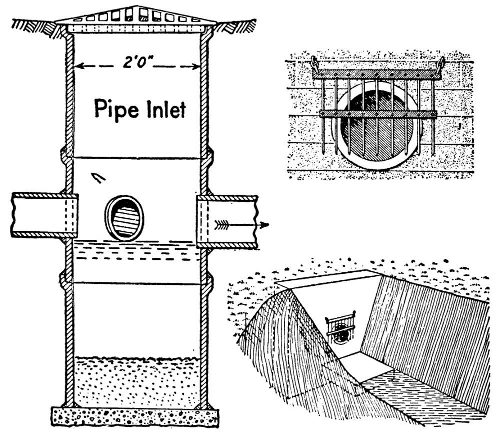

Of all problems, quicksand is perhaps the worst. The following suggestions may be helpful: Undertake quicksand drainage during the driest part of the season; if possible, after opening the drain into quicksand leave it until the water drains out so the sand may solidify and the drain be more easily completed; in some cases it is better to remove the last foot or so by hand, as action of the digging wheel seems to provoke the trouble; sod thrown in the trench and around the joints is practical for short distances; straw, sawdust, shavings, gravel and cinders are often used to good advantage; cemented sewer pipe may be found practical in some cases; a silt basin (Fig. 20) should be constructed on the line of tile as soon as possible after passing through the quicksand area and the deposits of silt removed when necessary.

Tree roots seldom interfere with a drain unless it carries seepage or spring water during the dry season. All trees such as willow, poplar, soft maple, elm and elder bushes should be removed from the location of a drain. They are likely to clog the tile with roots. Where it is desirable to leave a shade tree, cemented sewer pipe should be used for at least 50′ on each side of the tree position. In orchards and permanent crops, cut-off drains should be installed to remove all seepage water as this has a tendency to feed the tile drain during summer and thus give trouble by root development in the tile.

Always the outlet of a drain should be well protected. The last 8′ or 10′ should consist of a piece of iron pipe or sewer pipe. A retaining wall may be a necessity; so may be a concrete or stone block to spread the water and prevent it from eroding the earth at the exit. Protection of the mouth to prevent the trampling of cattle and horses is also essential and so is a grating, preferably hinged or hung from above, to prevent the entrance of small animals. (Fig. 20.)

Tile may be made of clay or concrete. They should have the following characteristics: Smoothness inside to reduce friction and promote rapid flow; hardness to assure durability, good shipping and handling qualities; good shape—cylindrical—not warped; clean-cut ends to assure good fitting; freedom from burnt limestone to prevent breakage due to slaking of the lime.