The following information on greenhouses comes from Five Acres and Independence by M. G. Kains. Five Acres and Independence is also available to purchase in print.

Greenhouses are a means to a highly profitable business. The best thing about them is that operation can be started on a small scale and built up into a most extensive enterprise. Many establishments throughout the country, which are now doing a business of anywhere from fifteen to fifty thousand dollars and more a year, had their start in a single small greenhouse. Some even started as a hobby, and one very large grower I know began as a boy by growing lily-of-the-valley in a little lean-to. The possibilities are tremendous for anyone willing to learn, make the investment, and work hard to build up a business. The work is interesting and healthful—an all-year’-round job in the sunshine—and it offers great opportunities for originality and development.

The kinds of crops which can be grown, the markets, and the channels of sale are very broad and varied. Success is dependent upon the location of the site, the size and type of equipment, the ability to grow good stock, to buy well for resale, to merchandise, and to make an inviting display. In some types of business one of these factors may be more important than others. A brief outline covering typical methods of operation which may be helpful to those who would enter this field, either on a full- or part-time basis, follows. Of course, the outline is general with emphasis put upon the kind of business a man can start with the least amount of previous experience and capital. It is by no means an attempt to give a complete review of the business. Excellent material for further study, written by experts in their particular line, is listed at the end of this chapter.

Roadside Greenhouse Store. This is the type of greenhouse business which can be started on the smallest initial investment and with the least amount of previous or related experience. Equipment consists of a store of greenhouse construction built in connection with a roadside stand. The greenhouse may range from a small prefabricated type up to a long and pretentious display house of semi-iron or iron frame construction as described under “Greenhouse Sizes and Types.” The primary reason for the greenhouse is to attract attention, provide good facilities for display and sales, as well as a place where blooming flowers and plants will keep well until they are sold.

A greenhouse gets the attention of everyone interested in plants and flowers because it is the symbol of the trade. It gives the place a professional atmosphere no matter whether the plants are grown in that actual greenhouse or not. In fact, very few plants and flowers are actually grown in the greenhouse from which they reach the final customer. The actual growing of most things is a specialized business. Of course, some plants may be grown in the greenhouse, but unless it is quite large, it wouldn’t produce enough to provide you with the good living which is possible through the sale of plants and flowers.

Many men do succeed, however, by “finishing off” seedlings and young potted plants. They do not attempt to raise their own flowers from seed, but buy young stock in 2″ pots, flats, or as rooted cuttings, and grow them to flowering stage. The propagation of plants has developed into a business in itself, and it is well to leave this job to those who specialize in it.

The greenhouse store should be built with wide lights of glass and high eaves in the front so the flowers and plants can be seen to advantage by all who pass along the road. Bedding plants and nursery stock can be displayed in the front and on each side. Covered stands with stepped-up benches extending out from each side of the greenhouse are excellent for the display of vegetables and other materials which require some protection from the weather.

The items which are greatest in demand are potted plants such as geraniums, begonias, African violets, ferns, ivies and other vines and foliage plants, cacti and succulents, dish gardens, hanging baskets and other novelties, as well as other seasonal potted plants. In the spring, and especially at Easter, flowering bulb plants like tulips, hyacinths, daffodils, and lilies are the big sellers, along with azaleas, hydrangeas, primroses, cineraria, gloxinia, cyclamen, and the like. If you want to go in for cut flowers out of season, roses, snapdragons, carnations, stock, sweet peas, calendula, gardenias, camellias, and orchids are among the leading all-year-’round items, but a refrigerator is needed to keep them fresh.

When the outdoor planting season begins, you have your rush season. Plants in flats, baskets, pots, and nursery stock really move–Sweet William, hardy carnations and chrysanthemums, candy tuft, petunias, marigolds, bleeding heart, lobelia, alyssum, forget-me-nots, hardy primroses, the geraniums, begonias, seedums, vines, and a host of other plants for flower beds and boxes. Husky seedlings of calendula, asters, zinnias, snapdragons, larkspur, blue lace flower, and salvia are also in demand.

Vegetable plants sell by the thousands, too, especially tomatoes, peppers, eggplant, broccoli, cabbage, and cauliflower. You can grow many of these in hotbeds and cold frames yourself, and buy more from others if you run short.

In the nursery line, hardy azaleas, taxus, hemlock, junipers, laurel, rhododendron, dogwood, rose bushes, lilac, flowering crabapples and cherries, and fruit trees are good items to sell to home owners for decorating their grounds. Many of these can be bought in the form of young plants and grown to popular selling size on your own land, but since you cannot do everything yourself, it is often better to buy the plants for resale from a wholesale nursery.

Throughout the summer and fall, cut flowers grown in your own fields are very profitable to sell. Gladioli, asters, zinnias, and dahlias are all popular, but by far the greatest demand is for chrysanthemums. If rooted cuttings are set out early in the spring, they can be forced into bloom early by darkening with black cloth. Flowers in early September are possible, and others not darkened can be had until frost.

Vegetables and fruits of all kinds grown on your own property, in season, and purchased from other farmers and in the market, are profitable to sell all year ’round. The fact that you have a farm gives people confidence that the produce is fresh and low-priced. While it is not possible for you to grow all of the stock you can sell, yourself, you need have no qualms about selling produce that you buy providing it is of good quality and reasonably priced. Your success in business year after year depends upon it.

Some roadside greenhouse stores also sell garden furniture, vases, pottery, trellises, garden ornaments, and the like. Of course, you cannot sell everything, and it is often well to specialize in certain items. Experience in the locality and in the business will soon tell you what articles are best. With a well-rounded-out stock and several specialties of the kind mentioned, it is easily possible to reach a sales volume of $500 to $1,000 a week.

Retail Florist and Grower. The retail florist grows only a part of the stock that he sells, depending upon the size and number of greenhouses that he operates. Usually he grows a general line of cut flowers and pot plants and buys the rest from wholesalers. If he grows more of one particular crop than he is able to sell retail, he can ship his surplus to a wholesale commission house for sale to other retailers at the current market price. During holiday seasons, however, most retailers are not able to grow a very large percentage of many of the things they need to fill the demand of their trade.

Some retail florists do not grow any of the stock they sell, but use the greenhouse for display, sales, and conservation of their stock.

Wholesale Grower. Wholesale growing is a very specialized business in which only one or two crops such as roses, orchids, carnations, gardenias, snapdragons, or pot plants are grown for sale through wholesale commission houses or direct to retail florists. Specialists in flowering shrubs such as azaleas and hydrangeas, and growers of ferns, vines, and foliage also sell through this market. To make a reasonably good living, the operator needs experience, skill and at least 12,000 sq. ft. of ground covered with suitable glass. Sometimes wholesale growers can also conduct a retail business in their immediate locality.

Mail Order Business. There are splendid opportunities, too, to build up a part- or full-time business through mail order sales of greenhouse specialties. Potted house plants, usually of a variety not readily obtainable in the open market, make the best items to sell. Of course, they should be of a type that are fairly easy to grow, pack, and ship. Sales are made through small-space advertisements placed in the garden magazines and in the garden pages of newspapers, and through direct mailing of literature to specially selected lists of garden enthusiasts.

The Vegetable Grower. The vegetable business requires a large investment to start with, for an acre of ground covered with greenhouses is needed to make a living. The greenhouses need not be of the most expensive type, however. They can be pipe or semi-iron constructions, such as described later. Lettuce, radishes, tomatoes, and cucumbers are the most profitable plants.

Greenhouse as a Supplement to the Farm. A greenhouse operated in connection with a farm is very advantageous for growing plants to set out in the field during the spring and summer. Production is much higher than in a hotbed or coldframe, and the greenhouse can be used to produce other profitable crops during the fall and winter.

The plants you grow yourself are far superior to those you can buy, and you can have them at the right time and in the particular strain or variety you want. In this way you can figure out how to have produce ready to market when prices are right, and you can grow it to a quality that will command higher prices.

A prefabricated greenhouse or one of pipe or semi-iron construction is suitable.

Greenhouse Sizes and Types. When you build a greenhouse, make certain it is built well no matter whether you put it up yourself or have a company build it for you. Be sure it is sturdy and durable, a good producer of plants and flowers, and that it has a heating system installed which will be easy to operate. Remember that it will be subject to every kind of weather condition—driving wind, rain, heat in the summer; snow, sleet, freezing cold in the winter. It will be warm inside and cooler outside, and consequently will be subjected to a large amount of moisture from condensation all the time.

If the greenhouse is properly designed and built in the first place, it will be efficient and trouble-free, leaving you to devote all of your time to growing, selling, and taking care of your business. On the other hand, greenhouses built of home-made or secondhand materials often become a headache, and the difference saved in the beginning is soon offset by continual patching and high operating expense. In a business of this kind you need to be free from worry to increase your yield and earnings.

The Materials. Cypress, redwood, and red cedar are the lumbers used in good greenhouse construction, because they will stand up under the conditions of moisture to which a greenhouse is subjected. The wood should be clear, free from sapwood, and air-dried for at least two years to give it proper strength and insure against warping. Reliable manufacturers always supply this kind of wood. Upland cypress, sapwood, and redwood cut from the higher sections of the tree are not suitable.

Second-hand materials are not worthwhile because it takes a great deal of time and skill to put them in proper condition. The bars are often split and the ends rotted. These sections must be cut off and framed on the right angle. It takes skill in carpentry to do it. In addition there is the old putty and paint to scrape off, and when you are finished you still have a second-hand house.

In buying any greenhouse, be sure the manufacturer supplies the woodwork cut-to-fit and framed on the ends. You can save on the materials by buying the woodwork in random lengths, but it takes skill in carpentry to do the framing, which usually costs more to do on the site than it does to have it done at a factory. When the wood is cut-to-size, the roof bars, ridge, sills, door frame, and all other parts are ready to slip in place and the work can be done by any handy mechanic.

If greenhouses are built with a steel frame, the steel should be hot galvanized after fabrication. This is important because black steel will rust quickly in the dense moisture and humidity. Nails, screws, steel fastenings, and hardware should also be hot galvanized to prevent rust and cut down the work of repainting. Fittings should be of malleable iron which does not crack or break.

Prefabricated Greenhouses. These can be put up anywhere, during any season of the year, with very little trouble. They are made in two and three-bench widths in sections formed by sash panels. The manufacturer ships them preassembled, ready to join together with bolts and screws. Anyone who knows how to use a hammer and screwdriver can erect them. The glass also comes cut-to-size and is put in place without putty. Deep glazing grooves in the wood and a caulking rope hold it in place. These excellent houses will remain as good as new for years.

There are two popular styles of prefabricated greenhouses: the English style built with slanted sides, and the conventional Colonial style. The sections are about 2 1/2 ft. long. Hence you can buy what you want and can afford to start with, and add to it later. Also, since they are portable and not a fixture to the land (unless built on a concrete foundation), they can be put up on rented property, and taken down and moved or resold. They can likewise be moved, with all the glass in place, from crop to crop. A crop can be started on one part of the land, and when it is finished, the greenhouse can be moved to another in a very short time. I have seen three men move a hundred feet in half a day.

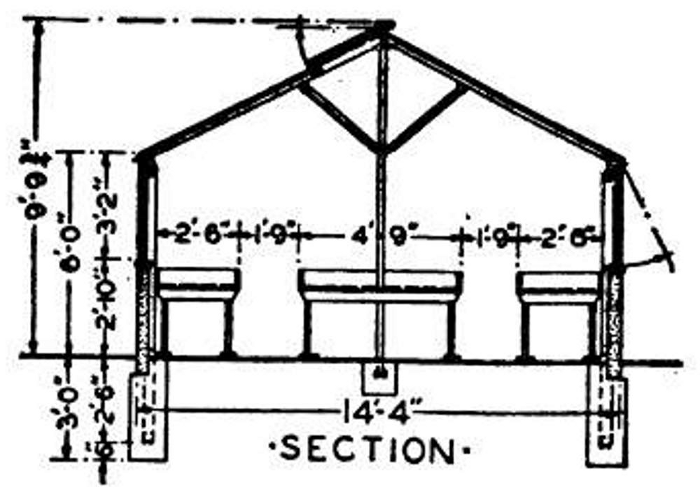

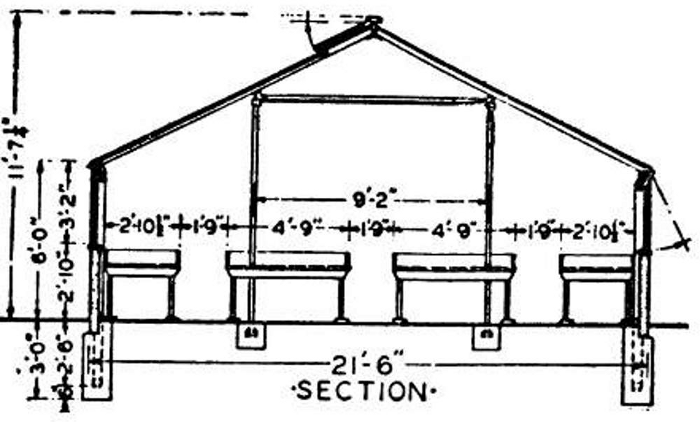

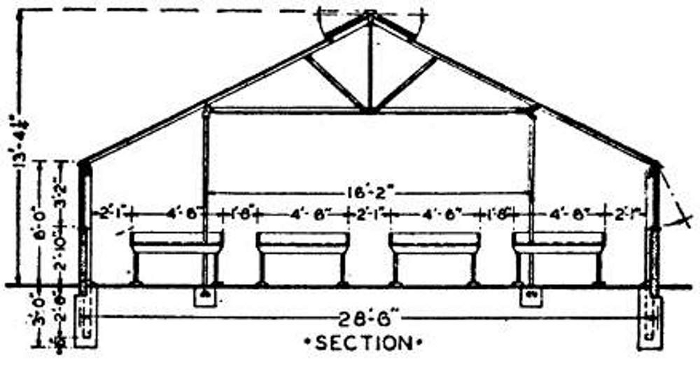

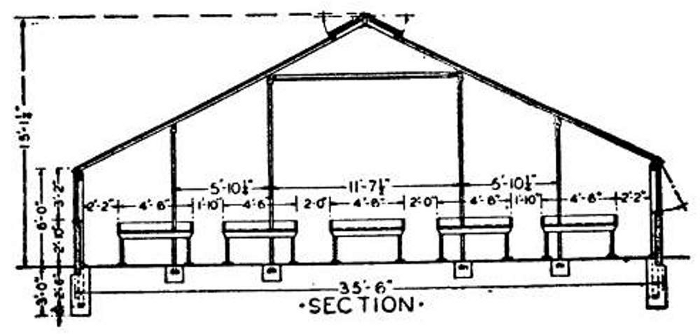

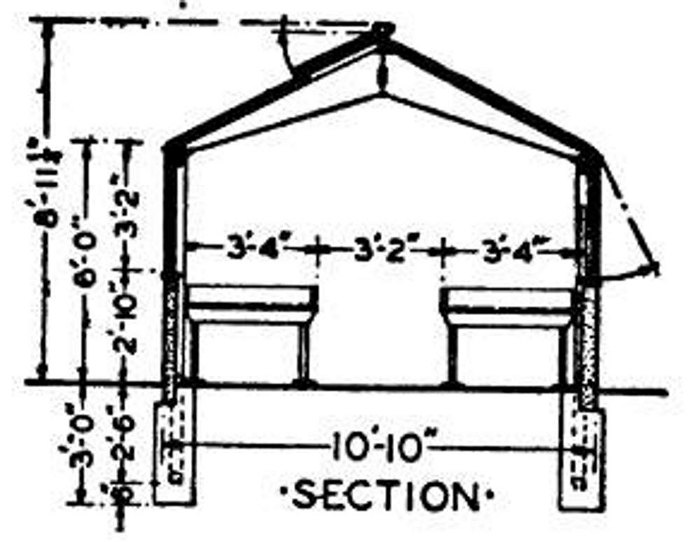

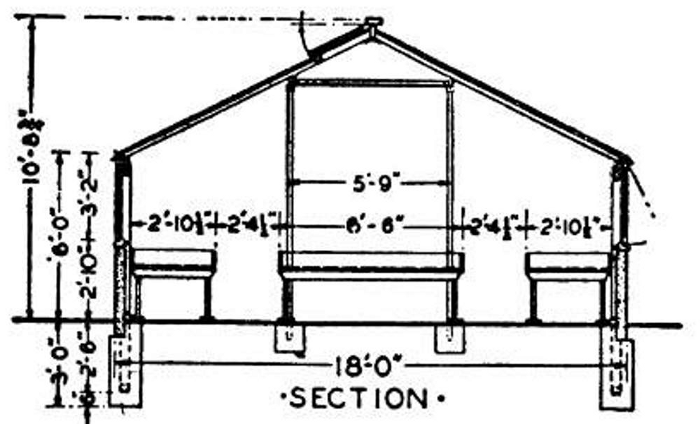

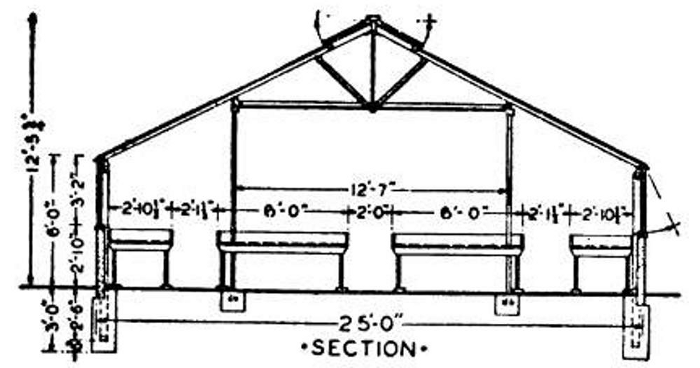

Pipe Frame Greenhouse. This type greenhouse is built with a frame of steel pipe and is most economical if you have pipe available or can buy it reasonably second-hand. The pipe is joined together with malleable iron fittings which can be purchased from manufacturers. The fittings make solid connections without the aid of special tools or machinery. A greenhouse of this construction is practical in widths up to 40 ft., and in any length.

Semi-Iron Greenhouses. This type construction is somewhat similar to the pipe frame, except that the side posts are made of flat steel and the roof supporting purlins, struts, and cross ties are of angle iron. It is a more economical house to put up than the pipe frame if you don’t have pipe available, because manufacturers supply the frame completely prefabricated and ready to assemble on your grounds without cutting or drilling. It is practical in widths up to 40 ft.

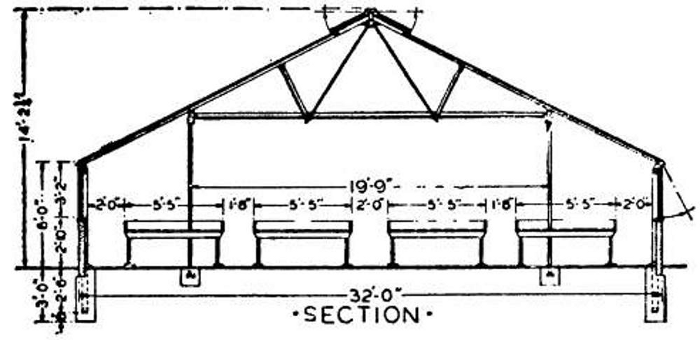

Iron Frame Greenhouses. In this construction, the greenhouse has steel rafters extending from the side posts up to the ridge to support the roof. It makes solid construction which can be built in widths up to 80 feet. A semi-iron or pipe frame house built wide would require a forest of interior columns to support the roof, because the roof is supported directly from the ground. In iron frame construction there are no columns up to 80 ft., and only 4 rows in 80 ft. So for a wide house, an iron frame is the most practical and the least expensive. In houses narrower than 40 ft., it is also desirable where interior columns would be a nuisance and extra-long service is more important than the lower cost.

Lean-to Greenhouse. A lean-to greenhouse is just half a greenhouse. It can be built in any of the above constructions against another building or wall. It is a mistaken idea to think they are economical and practical, however, because whatever is saved on the materials which would make up a full-span greenhouse is spent on flashing the structure to the other building and by other exacting requirements in building. What’s more, growing conditions are not as good as in a greenhouse since light enters from one side only, and the enclosures are difficult to heat, ventilate, and maintain at the even temperature necessary for healthy plant growth.

Gutter-Connected Greenhouses. Any of the above houses can be built in blocks of two or more houses connected at the eaves with a gutter. This construction is often desirable where land is at a premium. It makes several houses into one wide house, and saves part of the cost of building walls between them. Gutter-connected houses are often used for growing vegetables and are practical in areas where there is no danger from heavy snow loads.

You can build a greenhouse in several ways: have the manufacturer supply everything including the materials and men to do the erection on your land; buy the materials from a manufacturer, hire a foreman from him to supervise the work, and furnish handy mechanics to help him; buy the materials and plans alone and do the building yourself with the help of a carpenter or handy man.

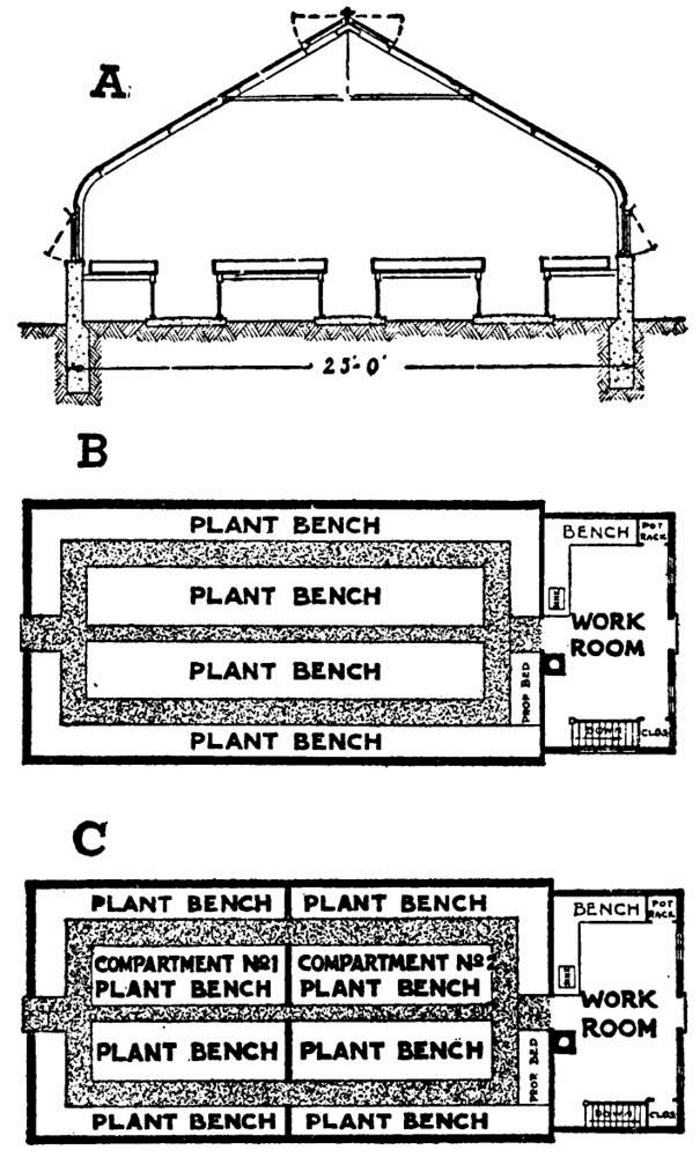

Widths and Lengths. Always be sure to build the greenhouse large enough to start with. Many people make the error of thinking they are choosing one large enough only to find it soon becomes overcrowded and an extension must be added the first year.

Houses from 15 to 50 feet wide are suitable for display purposes and for the growing of miscellaneous pot plants and most cut flowers. Wider houses are used by growers of roses and specialty crops.

For attractiveness and economy, always build the greenhouse in good proportions—longer than it is wide, yet not too long and narrow. Good dimensions are 10 ft. by 15 to 20 ft., 15 ft. by 25 to 30 ft., 25 ft. by 50 to 75 ft. If the greenhouse is built wide and short, or long and narrow, it will cost more for the amount of space enclosed because the ends, ventilators, and doors do not increase proportionately as the house becomes wider and longer. For example, a house 25 by 30 ft. will cost much more per sq. ft. of ground covered than one 18 by 40 ft.

Walls. The walls of a greenhouse are built of clapboard, shingle, brick, poured concrete, concrete or cinder block. The one which fits in with the surroundings and matches those of existing buildings is best, because the wall construction has much to do with the appearance of the structure. Greenhouses which are built as detached units need a wall only about 8″ below grade, because they are heated. Greenhouses attached to other buildings require a foundation extending below frost so they will not pull away from the building with the contraction and expansion of the ground when it freezes and thaws.

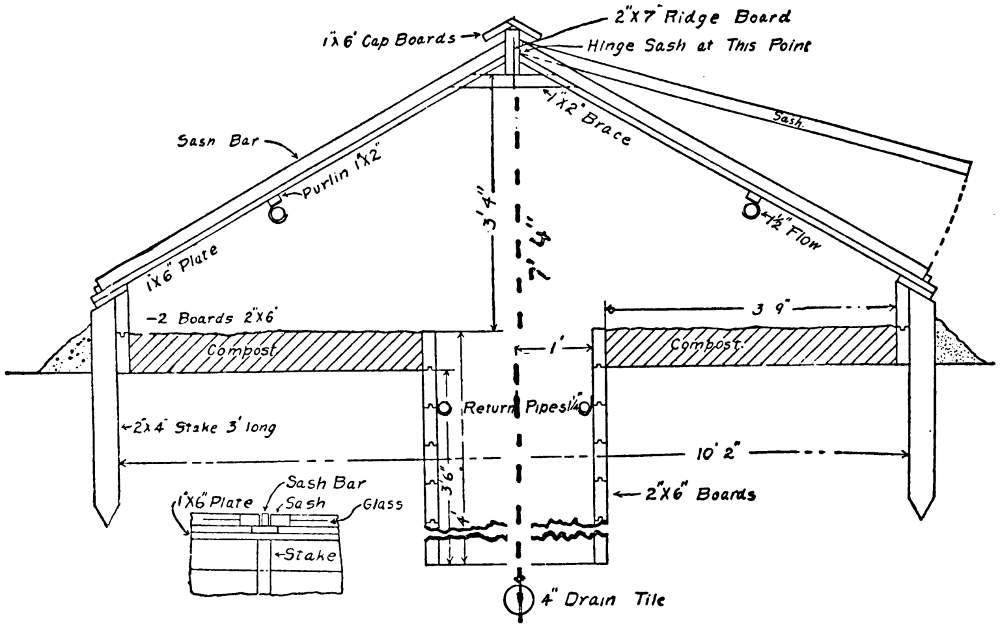

The Heating. Greenhouses are usually heated by hot water. Those built in large groups are sometimes heated by steam and require night firing or automatic equipment. Hot water is best for the smaller greenhouse or greenhouse group because the heat is more even and constant.

The radiation is conducted by means of lines of 1 1/2″ or 2″ pipe running along the wall or underneath the benches. Circulation from the boiler can be by gravity or motorized electric circulators. There are two types of gravity circulation. One is a flow and return coil circulation. The boiler is located in a cellar or pit deep enough so the top of the boiler is below the heating coils. The other is a gravity overhead feed main system suitable for small greenhouses. It has a single overhead feed main and single return coils. The return ends of the coils are connected together through a trench to the boiler. The boiler is located in a pit deep enough so the crown sheet is below the coils. The deeper the boiler, the faster the circulation. Both systems require a tank to take care of the expansion and contraction of the water.

A forced circulation system can be installed without the trouble and expense of building a cellar. The boiler is located on grade and the hot water is circulated by means of an electric circulator.

If the greenhouse is connected to, or located near, an existing building, heat can usually be supplied from the same boiler that heats the building, whether it be a steam or hot water boiler. The greenhouse should always be heated by hot water, and if it is connected to a steam boiler, hot water from the boiler can be circulated by an electric circulator.

The boiler which heats the greenhouse should always be large enough to maintain a firing period of 8 to 10 hours without attention, and if coal or artificial gas is used for fuel, it should be located in a separate building, for the fumes from these fuels are detrimental to plant life. If heat is by oil or natural gas (not mixed gas), the boiler may be located in the greenhouse.

Automatic firing with a stoker or oil burner is always desirable because the heat in the greenhouse can then be thermostatically controlled and you hardly have to think about it from one season to the next.

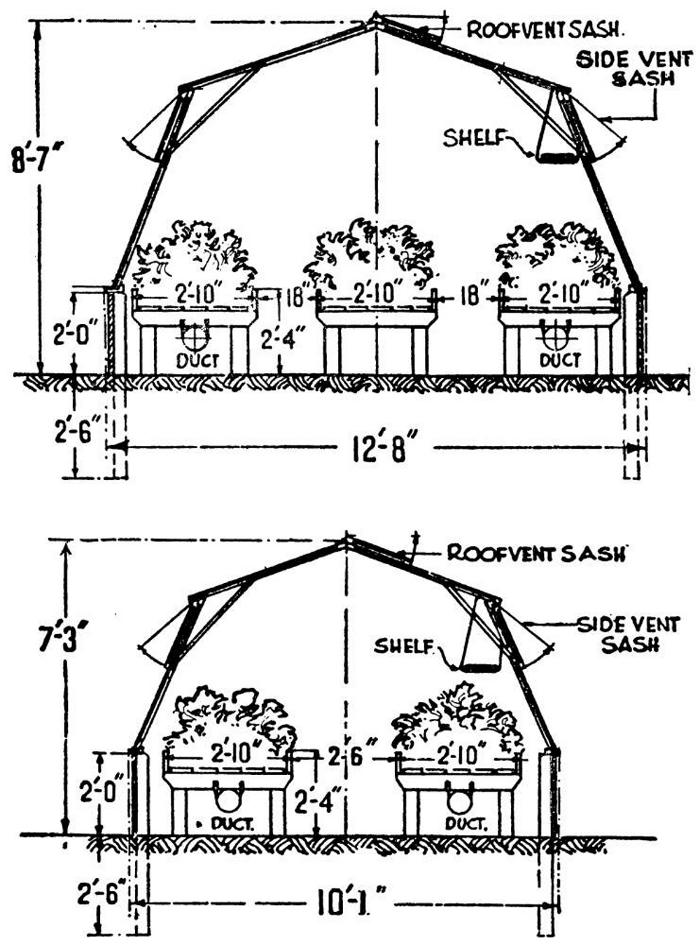

A less expensive method of heating with forced warm air is also possible in smaller greenhouses. It is similar to the so-called air conditioning system frequently installed in small homes. It consists of an oil heater equipped with a motor driven fan with warm air ducts installed under the benches. The fan sends the heat down where it is needed, and the flame is thermostatically controlled.

Books, Bulletins, and Catalogs. There are several books well worth reading for further information on greenhouse construction, management, and plant culture. Commercial Flower Forcing by Alex Laurie and D. C. Kiplinger is a textbook on greenhouse management and plant culture which is crammed full of practical as well as scientific information which every operator should have. Commercial Floriculture by Fritz Bahr is a very sound book on the florist and nursery business written by a successful and experienced operator. It tells you when and how to start a business. Ernest Chabot’s Greenhouse Gardening for Everyone covers construction and gardening from coldframes and hotbeds to greenhouses. It is written for the beginner and will be helpful to those starting out with a small greenhouse.

The Agricultural Experiment Stations publish excellent material on greenhouse equipment and plant culture. These bulletins contain the latest data on a wide variety of subjects and are distributed without charge. You have only to write for them. Catalogs and literature published by greenhouse manufacturers are also helpful. They contain detailed information on methods of greenhouse construction and heating.

After you become established in business, it is particularly advisable to subscribe to one of the nursery and florist trade papers. They contain not only news and articles of value, but also advertisements of the best buys in stock and other merchandise.