The following information on the Mauser automatic pocket pistol comes from Chapter 35 of Mauser Rifles and Pistols by W. H. B. Smith. Mauser Rifles and Pistols is also available to purchase in print.

Mauser pocket pistols were manufactured in only two calibers for general production. The first, introduced in 1910, was for the 6.35mm Browning cartridge which we know as the .25 Automatic Colt Pistol cartridge. It was followed by an arm of 7.65mm caliber of the same design, differing only in dimensions as required by the increased caliber and by the finger serrations on the slide. In 1934, a new model (Neues Modell) was introduced which varied mechanically very little from the original type. In this new model, however, the grip was narrower and instead of stocks screwed to each side of the grip frame, a single shaped grip of wood which covered both sides and the back strap of the frame was used. This grip was worked over the back of the steel grip section of the receiver, thrust into place, and then fastened with a stock screw.

Because of variable types of grips used, this pistol as encountered may seem to differ from the one pictured here. This illusion is produced by the fact that differently shaped grips of wood could be obtained to provide a different pitch to suit the hand of an individual shooter.

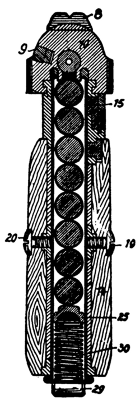

The dimensions and characteristics of the .25 caliber are as follows: Overall length, 5.25 inches, barrel length 2.96 inches, height 4 inches, thickness 15/16th inch, weight, 15 ounces, magazine capacity 9 cartridges.

The dimensions and characteristics of the .32 caliber are as follows: Overall length, 6 inches, barrel length 3.39 inches, height 4.5 inches, thickness 1.12 inches, weight, 21 ounces, magazine capacity 8 cartridges.

Characteristics of the .32 ACP Cartridge

The characteristics of the .25 Automatic Pistol cartridge have been given in Chapter 30. Following are the characteristics for the .32 Automatic Colt Pistol cartridge, known in Europe as the 7.65mm Browning: This cartridge shoots a lead bullet with a full metal jacket weighing about 74 grains at a muzzle velocity of approximately 965 feet per second. The striking energy at the muzzle is about 152 foot pounds. The bullet has a penetration in 7/8 inch board of soft pine of 3 boards at a distance of 15 feet from the muzzle.

The Pistols

These pistols are customarily of fine material, workmanship and construction. They are equipped with a thumb operated safety but do not have the automatic grip safety found in the Colt type. These are striker operated weapons. A spring housed within the striker pin is compressed when ready to fire. Upon release by the sear the spring drives the striker pin forward to fire the cartridge. When the striker is cocked, the head protrudes through a slot or hole in the rear of the slide. Thus, when this pin can be felt or seen, the striker is cocked. Note, however, that this does not necessarily mean that there is a cartridge in the chamber, as this is a cocking indicator and not a cartridge indicator. This good feature also has certain drawbacks. If the pistol is dropped and hits on the striker-projection, it is possible at times for the striker to be jarred off the sear to fire the chamber-cartridge.

A magazine safety is also an integral feature of these arms. When the magazine is withdrawn, the weapon cannot be fired. This prevents danger from a loaded cartridge remaining in the chamber when the magazine has been withdrawn. An automatic interceptor functions when the slide recoils to break the connection between the trigger and the sear, thereby preventing the firing of more than one shot for each pull of the trigger. The thumb safety is of unusual design, and consists of two parts. A thumb lever on the left side of the grip behind the trigger is pushed down to positively prevent firing. This also locks the slide so that the breech cannot be opened. Pressing the spring-controlled button directly below the thumb lever releases the lever and sets the pistol ready for firing.

When the last cartridge has been fired, the slide is held open. Inserting a loaded magazine, then drawing back slightly on the slide will release it, and allow it to go forward under the pull of the recoil spring to chamber a cartridge and leave the weapon ready to resume firing. The substantial grip, good balance, absence of projecting parts and flat shape make this a good pocket pistol. This model belongs to the blowback category listed by the Germans as “Mit Federverschluss” or “with spring lock.”

Because of the comparatively low power of the cartridges employed, a secure breech locking system is not necessary. The weight of the moving parts and of the springs resisting the opening of the breech hold the breech closed long enough to permit the pressure to drop before opening appreciably.

Loading

The arm is loaded in standard fashion. A loaded box magazine is inserted in the grip from below and pushed in until the magazine catch locks and holds it securely. The slide in this arm is of unusual design and does not enclose the entire top of the barrel in common pocket automatic pistol fashion. However, it is machined at the rear to provide the customary gripping surfaces, and when this breechblock-slide is drawn back it cocks the striker and permits a cartridge to rise in the magazine. When the grip on the slide is released, the recoil spring housed below the barrel acts to draw the slide forward to chamber a cartridge and leave the weapon ready for firing.

Barrel and Trigger Design

The barrel design is unusual in that it carries the front sight at its forward end, while its underside is provided with projections to permit locking it firmly to the receiver as the rear projection is worked down into a slot in the receiver, and the recoil guide spring rod inserted from below the muzzle passes through a ring under the barrel in the front projection.

The trigger is equipped with a heavy boss having a thick pin milled out of the receiver on the left side below the breech. There is a nose above and to the rear of this boss which engages with the interceptor block placed above it. This interceptor block is pivoted to the tail of the sear.

Interceptor Action

A small coil spring below the interceptor acts to thrust the upper face of the interceptor through a groove in the receiver extending up into a corresponding groove in the underside of the slide. When the slide recoils, its solid surface hits this interceptor face and drives it down inside the receiver. In this position, the interceptor is drawn out of contact with the trigger nose. Hence, while the sear can catch and hold the striker in rearward position, the trigger cannot come into contact with the sear lever to release the firing mechanism until the slide is fully forward and closed and the trigger is released to permit its spring to push it forward so that the interceptor (or interruptor) block can rise under influence of its spring into the cut on the underside of the slide. The sear is a long lever operating on a pivot. Its rear upper end is designed to catch in a slot in the underside of the striker as the striker is forced back during rearward motion of the breechblock-slide.

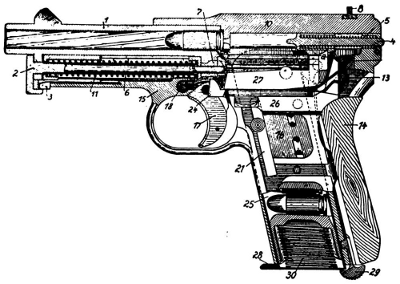

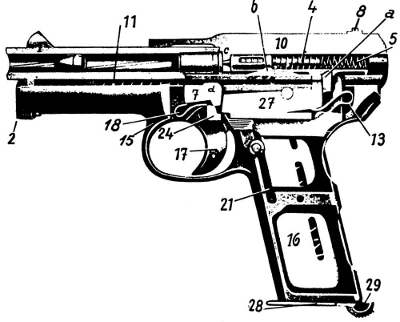

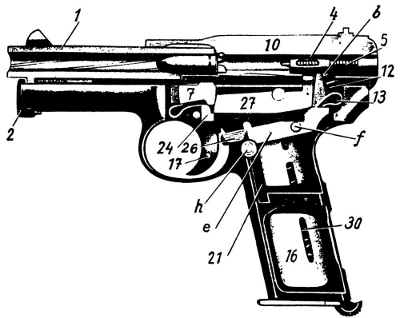

Parts Key To Two Drawings Above

1. Barrel

2. Barrel Retainer

4. Striker

5. Striker Spring

7. Interceptor

10. Slide

11. Recoil Spring

12. Ejector

13. Double Spring

16. Magazine

17. Trigger

21. Safety Lock Spring

24. Trigger Catch

27. Sear

e. Thumb Safety Bar

f. Safety Pivot Pin

h. Safety Release Button

Operation

When the trigger is pressed, it rotates on its pin and a small catch at its upper rear is elevated to hook under the edge of the sear lever. This depresses the rear of the pivoted lever, meanwhile compressing the sear spring below, and draws the sear out of contact with the striker.

The compressed striker spring within the striker tube thrusts the striker forward to hit the cartridge in the chamber and discharge it. As the bullet travels down the barrel, the slide starts to move much more slowly to the rear. The extractor in the face of the breechblock end of the slide carries the empty cartridge case back with it. The forward arms of the slide below the barrel carry the recoil spring back and compress it around its guide below the barrel. As the slide opens, exposing the breech opening for ejection, a solid surface on the slide on its under travel side on the left runs over the head of the interceptor (or interruptor) block and pushes it down. This forces the trigger catch below it down to a point where it cannot engage with the sear lever. The sear spring thrusting the rear end of the sear lever up, enables it to engage in the underside of the striker cut as the striker reaches full compressed position.

At the end of the recoil stroke, after the empty cartridge case has hit the ejector and been hurled out of the pistol, the magazine spring forces a cartridge up into line. The recoil spring, now fully compressed, reasserts itself and drives the slide forward to chamber the top cartridge from the magazine. When the trigger is released momentarily, its spring moves it forward and also thrusts the interceptor block up into its cut in the underside of the slide. At this point, the trigger catch is again close to the sear lever and another pull on the trigger will fire the next shot.

Safety Design

The safety is of unusual design. It has a spring operated arm pivoted to the receiver. When the thumbpiece at the forward end of this arm is pulled down, the rear end of the safety bar rises into contact with the rear end of the sear, making it impossible for the sear to release the striker under any condition. Furthermore, a tip on the end of the safety is thrust up to double lock the striker. Both the sear and the striker are thus solidly locked. When the spring operated button below the thumb lever is pressed, the double action sear spring and the flat safety spring function to thrust the rear of the safety lever or bar down out of engagement and thereby pivot the front thumbpiece up ready to be applied again when necessary.

This pistol is an essentially simple design. Like the Mauser Military Pistol, it has a maximum of built-in contacts and bearing surfaces and does not depend upon pins or screws for its assembly.

Stripping

Dismounting this arm is quite simple: The recoil spring guide protruding with its locking edges from the receiver below the muzzle, is pressed and turned to free it. It is then pulled forward for removal. The slide is then drawn back over an empty magazine. The barrel may then be lifted straight up out of the receiver. Inserting a magazine and then withdrawing it will release the slide and permit the recoil spring to pull it forward. The slide and recoil spring assembly will come off the receiver runners to the front. The striker and extractor may be removed from the slide. Removing the stock screws and working the stock off the back of the receiver grip, then working off the receiver lock plate on the left side will expose all the action with its interlocking parts for removal if necessary.

Click here to purchase Mauser Rifles and Pistols in paperback

Return to Mauser Rifles and Pistols Table of Contents