The following information on the Mauser C96 and other Mauser pistols comes from Chapter 28 of Mauser Rifles and Pistols by W. H. B. Smith. Mauser Rifles and Pistols is also available to purchase in print.

Paul Mauser invented the first really successful military automatic pistol. While numerous experimental models had been manufactured at an earlier date, it was not until Mauser in 1896 patented his military automatic pistol that a weapon of reliable design was produced.

The diagram shown below [towards the bottom of the page] is from the original specification filed by Mauser. It is remarkable in that this design was so right initially, that in all the years of manufacture from 1898 when it was first put on the market until 1945 when its manufacture was halted by the termination of World War II, only minor design changes were possible in this weapon.

In his patent specification Mauser described his invention and said that it had for its object, “A magazine repeating fire arm with a movable barrel, in which the recoil caused by the shock is used to unlock the bolt and open the breech, to eject the empty cartridge case and to work the firing mechanism, as well as to compress a number of springs arranged in such a manner as to effect the loading of a fresh cartridge, the reclosing of the breech and locking of the bolt and the advancing movement of the barrel. Upon these principles which are already partly known, I have devised a magazine fire arm in which all previous experiences in respect to this class of arm have been carefully taken into consideration, not only with regard to its ballistic qualities, but especially by the peculiar skillful construction of the component parts, and the manner of connecting them without the aid of screws; it may, therefore, be considered that the improved fire arm is in every way well adapted for military purposes.”

This remarkable achievement of Mauser’s in producing a pistol in which parts were made to interlock so that screws and pins were not necessary to its design has remained an outstanding achievement in firearms history.

The explanation given of the operation of the original drawing is as follows: “This is a vertical longitudinal section of an automatic repeating pistol. The barrel A has an extension A1 forming a breech casing for the breech bolt B, which is held forward by a spring supported by a pin A2 passing through a slot in the breech bolt. The breech bolt is locked in its closed position by a hinged locking piece C, having a pivot forming a projection against which the mainspring D acts. When the pistol is discharged the barrel recoils a short distance, during which a projection on the locking piece C is drawn down into a recess in the block C1 by the action of the mainspring D, and the breech bolt is thereby unlocked. The barrel then stops, but the breech bolt B continues to recoil, cocking the hammer D1, opening the breech, extracting the spent cartridge, and allowing a fresh cartridge to rise from the magazine B1 into line with the breech bolt. The reaction of the breech bolt spring carries the bolt forward again to load the weapon and close the breech.”

Quite as remarkable as the development of this pistol was the development of the cartridge which accompanied it. This cartridge is substantially the same today. Correctly known as the “7.63mm Mauser” it is often called the .30 Mauser. The actual caliber is .3008-inch.

Cartridge Specifications

The case is bottle-necked and rimless and positions on the shoulder in the chamber. The original muzzle velocity was about 1350 feet per second and with different loadings and different barrel lengths in modern ammunition it may run as high as 1475 feet per second. The breech pressure is extremely high for a pistol cartridge, being approximately 30,000 pounds per square inch. The cartridge has appeared with full patched bullets, soft nosed bullets and even hollow point bullets. Ammunition for this weapon was manufactured by all U.S. cartridge makers before World War II. The usual bullet weight is 85 grains with a cupro-nickel jacket.

This pistol was very extensively used by the Boers in South Africa in 1898, shortly after its introduction, and was considered a very formidable weapon. The magazine holds 5 or 10 cartridges which can be stripped in through the top of the action from a clip (exactly as in the Mauser rifle) into the box magazine ahead of the trigger.

When the bolt is pulled back it cocks the hammer and the magazine follower rises to hold the action open for loading. A clip of cartridges is inserted in the clip guides and the cartridges pushed down into the magazine. When the clip is pulled up out of the top of the guides the compressed spring drives the bolt forward to chamber a cartridge, leaving the weapon ready to be fired. In original tests it was fired at the rate of 6 shots per second and better than 80 shots per minute. The extreme range is well over 1000 yards and the pistol was provided with a detachable shoulder stock which served as a holster for the pistol itself when not in use.

The original 1898 production had a 4.75 inch barrel including the length of the chamber. The hammer is large and rises into the line of sight as it hits the firing pin. This blocks the line of vision of the rear sight except when the pistol is at full cock. The rear sight is a plain V which is not adjustable.

The front sight is part of the barrel forging itself. A thumb safety on the left side of the receiver is pushed down to lock the hammer safety when the weapon is cocked.

This original design was altered very shortly after its introduction, being replaced with a model having a 5.5 inch barrel, a lower hammer which does not interfere with the line of sight, and a tangent rear sight, graduated from 50 to 700 meters and mounted above the barrel extension. This was the weapon widely used in the Boer War.

One of the earliest and most enthusiastic users of the original Mauser pistol was Winston Churchill, who at that time was a Lieutenant in the 21st Lancers. He carried the pistol at the battle of Omdurman, and in his history of that campaign, gives a graphic account of how he was able to shoot his way out of a native trap because of the large magazine capacity and the rapidity of fire. His stirring account of the episode is one of the classic stories of the Sudan campaign. These early models use 4-groove rifling. In 1905 a 4-inch barrel model, having a somewhat squarer rib than usual, a 5-shot magazine, and a very large hammer, with an exceptionally large hammer hole was introduced in small quantity. This too, had 4-groove right twist rifling.

The 1912 and Subsequent Models

In 1912, a 10-shot model with a 5.5-inch barrel was reintroduced. The rifling was changed to 6 grooves, right hand twist, having very narrow lands. Some slight details in the action were changed at this time. A broader and shorter extractor was included, a smaller hammer, the safety lever was designed to be pushed upwards to produce the safe position, the striker (which heretofore had been retained by a sliding plate dovetailed into the rear of the bolt) now had two lugs turned on its head, the head itself being cross cut to accept the point of the cleaning rod furnished with the pistol—this was used to remove the striker when necessary. Pushing the striker in against this spring and giving a half turn to the right disengages the lugs, permitting the striker to be withdrawn.

Shortly afterwards other minor changes were made. The T section of the rear of the bolt were made broader, its under lugs which serve to rock the hammer back, was made larger and longer and extended to the rear locking recess, the front mainspring plunger was pierced to take the rocker (prior to this time the rocker had rested in front of the plunger). The front plunger was given a tail to project through the claw of the receiver as far as the sear lever to serve as a disconnector. While the front plunger is pressed back by the rocker, the tail prevents the sear lever from being elevated by the trigger and also serves to hold the front plunger.

The pivot of the safety lever engages directly in the safety bent on the hammer instead of using a separate bar as heretofore. When it is pushed upwards, a projection on the pivot enters the safety bent, a slot extending from the recess straight upwards. A second bent is provided to receive the pivot of the safety lever when the hammer is down. This feature serves to prevent the arm from being cocked if the safety is applied.

The trigger and its spring were mounted directly on the receiver (heretofore they had been on a separate block). This requires only a narrow slot in the claw of the receiver above the triggerguard.

This variety fitted with a tangent sight graduated from 50 to 1000 meters, was very extensively used during World War I. Although never an official German pistol, it was widely manufactured and issued to troops as a substitute weapon.

World War I Conversion

During World War I, large numbers of this model were converted to take the standard German army cartridge, for the Pistole 08, or 9 millimeter Luger cartridge as it is known in this country. These pistols are distinguishable from the standard 7.63mm type by the figure “9” usually painted or burned into the grips. This type of pistol used the standard 9mm Luger cartridge as manufactured in the United States, prior to World War II.

With the ending of World War I, the Mauser factory was not permitted under the terms of the treaty of Versailles to manufacture the 7.63mm with the standard barrel. By a subterfuge, it was decided that the pistol might be manufactured with a barrel a fraction under 4 inches, including the chamber length. This model had the same action as the standard Mauser used during the War, but its grip was modeled after the old 1905 model. This type will often be found with Swiss markings. It was also widely distributed in the United States as an export weapon, fitted with specially shaped Franzite grips. It has the standard 50 to 1000 meter sight. This model, introduced shortly after 1920, is often popularly referred to as the “Bolo” Mauser from the fact that very large numbers were shipped into Russia, where they were popular with the Bolshevik group striving for power at that time.

At this juncture it might be well to point out that this pistol in this caliber from its very inception was very widely accepted throughout all parts of Russia and Siberia. It was and is one of the most popular weapons ever used in the Orient. The official Russian army automatic pistol cartridge today is the 7.63mm Mauser cartridge with a somewhat lighter load, although officially called “7.62mm.”

The next alteration was in 1926 when the barrel length was set at 5.25 inches which kept it in the specifications set forth in the Versailles Treaty.

The changes made at that time include the following: The safety lock was altered to require pushing the thumbpiece up to set the safety, though it worked on the same principle as heretofore. The pivot pierces the side of the receiver and enters a recess in the side of the hammer to serve as a safety bar. This hammer recess is cut to enable the hammer to be released when the safety is applied but to halt the movement before it can touch the firing pin head. This is a so-called “universal” safety to permit the hammer to be lowered in complete safety on a loaded chamber.

The sear is extended further back on the left outside the receiver and enters a recess in the safety lever so cut as to permit sear movement only when at full fire or at full safe position. Utilizing this system, it is possible to load the firing chamber, set the safety and then merely press the trigger to drop the hammer safely. Pushing the safety off, leaves the arm ready to be cocked for firing the chamber.

The Mauser Universal Safety Lock was officially included in all models later manufactured by Mauser. This model was widely marketed as the Model 1930.

This universal safety lock will also be found on many of the short Bolo Mausers, indicating that production was continued in the 1930’s.

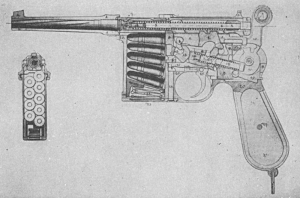

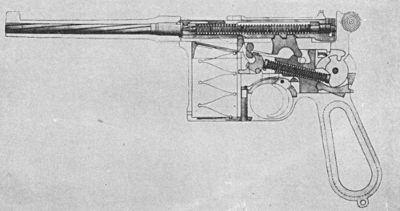

Mauser C96. Mauser Automatic Pistol. Left Side Phantom View, And Rear Detail Of Magazine (For image above)

This drawing shows all details of the weapon in closed position with all parts at rest except magazine spring which is under compression.

In the drawing an empty cartridge case is shown in the firing chamber. In actual operating conditions, this could not happen except at the instant of discharge. When this weapon is discharged, the barrel and breechblock recoil together and the empty cartridge case is ejected.

The barrel (A—at all points) and its rear barrel extension are forged from a single unit. The breechblock travels in the barrel extension. The front sight is also part of the barrel forging. Note that while there is a heavy recoil spring positioned around the firing pin, the firing pin itself has a small spring at its forward end within the heavier recoil spring which serves to withdraw the point of the firing pin from the primer of the fired cartridge as the weapon recoils. This prevents firing pin breakage. The locking block (8) is rising through the cut in the underside of the barrel extension to engage in its notches in the breechblock (2).

The detail view shows the construction of the magazine and its follower. As the cartridges are stripped down in the magazine through the top of the action, the shape of the follower forces the first cartridge to the right and zigzags each succeeding cartridge. Lips at the top of the magazine well prevent the cartridges from coming out accidentally.

To unload this weapon, it is necessary to move the breechblock back and forward once for each cartridge, which must be inserted in the chamber and ejected; or as an alternative method, the bottom of the magazine may be removed to permit withdrawal of the floor plate, magazine spring, follower and cartridges.

Mauser C96. Mauser Automatic Pistol. Table Of Parts (For same image above)

1. This is the barrel, whose rear forging forms a barrel extension with guides for travel in the receiver. The rear of the extension is hollow to receive the breechblock inserted from the rear. In early models, such as this one, the rear sight was also part of the breechblock forging. In later models, separate rear sights were used.

2. The breechblock with gripping wings at its extreme rear protruding from its entrance to the barrel extension in which it is housed.

3. Recoil spring mounted around the striker.

4. Recoil spring compressor. This is a block inserted through the side of the barrel extension and through a slot in the breechblock. Its forward surface serves as a compression point for the rear of the recoil spring when at rest. As the breechblock is drawn back, the recoil spring is compressed against this block.

5. Firing pin or striker.

6. Firing pin spring around point. Its diameter is reduced at its front end and it serves to draw the firing pin back into the face of the breechblock immediately after it has been driven forward by the blow of the hammer.

7. Extractor. This is a claw dovetailed into the top of the breechblock. It is of spring steel construction.

8. Locking block. It is slotted through its center and rests on a receiver projection directly below it. It is supported at its ends (at A and A) in projections on the sidewall of the receiver.

8-forward. The tooth marked “8” is a forward frontal projection of the lock. It is engaged by A8, the rocker below it.

A8 Bolt rocker. During the recoiling action, this rocker pressing on the tooth of the bolt lock produces the action which draws the locking piece of the piece 8 down out of engagement to unlock the weapon.

9. Ejector. This is a projection on the receiver in this arm.

9 lower and rear. These points indicate projections on the left side of the receiver in which parts are housed.

10. Hammer.

11. Hammer axis pin.

20. Ribs at top edge of receiver in which barrel and breech mechanism slide.

21 and 22. Magazine follower and spring.

23. Magazine floor plate.

24. Magazine bottom attaching screw.

20. Parts of receiver.

A7. Mainspring and guide.

21. Stocks. These are removable and are attached by the only screw used in the pistol.

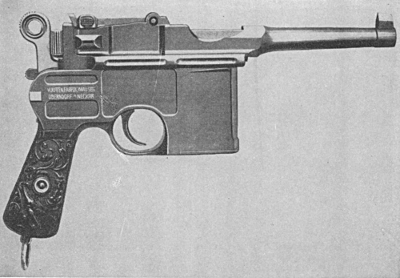

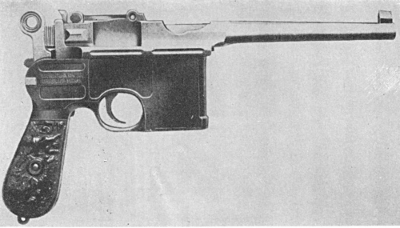

Mauser C96. Mauser Automatic Pistol With Shoulder Stock Attachment

The rear of the pistol grip is slotted to permit an engagement lug at the forward end of the shoulder stock to be thrust up to act as a secure locking unit. The shoulder stock is usually of wood and is hollowed out to act as a holster for the pistol when not in use as a shoulder piece. The button seen at the rear of the stock is a spring catch which opens the hinged butt-plate to permit insertion of the pistol for carrying.

The range of this arm is in the neighborhood of 1,000 yards. Since the sighting arrangements for use as a pistol and use as a shoulder arm are quite different, best results cannot be obtained by attempting to use the weapon as a dual purpose arm. However, when sights are properly adjusted for shoulder firing, this is an effective arm at very much greater than ordinary pistol ranges.

The stocks shown are those originally used by Mauser and are not typical of the plain grooved wood stocks later supplied.

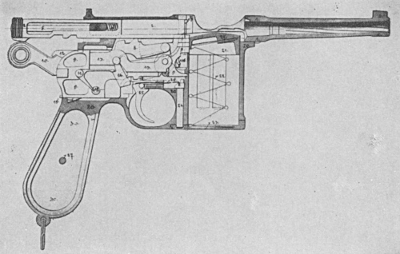

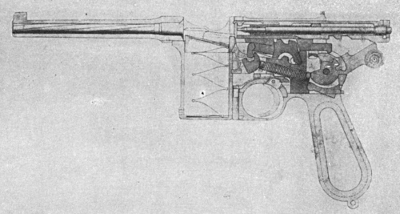

Mauser C96. Mauser Automatic Pistol. Left Side Phantom View With Action Closed And All Parts At Rest

The barrel and barrel extension, which travels in the receiver and which houses the firing assembly, are forged from a single unit in the genuine Mauser manufacture. At the instant of recoil, the barrel and the breechblock are securely locked by action of the toothed prop-up locking block seen with its teeth engaging in the underside of the breechblock. These teeth rise through a cut in the underside of the barrel extension to engage with notches in the underside of the breechblock when the action is fully home.

During the opening recoil movement as the weapon is discharged, the barrel and extension travels back locked with the breechblock. When the barrel hits its stop and its travel is halted, the prop-up block is far enough back that it can be cammed down out of engagement. This leaves the breechblock free to travel to the rear, to extract, eject and ride over and cock the hammer. The heavy coil spring positioned around the striker is not a striker spring. It is the recoil spring which serves to drive the breechblock forward on the loading stroke, since it is compressed during rearward movement of the breechblock. The coil spring with guide below the hammer is the mainspring. A small striker return spring is positioned just to the rear of the striker point.

Mauser C96. Mauser Automatic Pistol. Left Side Phantom View Showing Action Open And Magazine Empty

When the last cartridge has been fired, the magazine follower rises, and prevents forward movement of the retracted breechblock.

A comparison with the closed drawing will show the length of recoil of the barrel. The recoil spring is seen held compressed ready to drive the breechblock forward when released. The locking block has been cammed down, and the engagement notches in the underside of the breechblock may be seen.

The breechblock riding back over the hammer has rotated it about its axis pin causing its toe to thrust forward against the mainspring guide and thereby compress the mainspring.

When the weapon is open in this condition, a clip loaded with 10 cartridges is inserted in the feed guide. The cartridges are stripped down into the magazine with the thumb exactly as in the case of a Mauser rifle.

When the clip is pulled up out of the action, since the magazine follower is now down in the magazine well with cartridges on top of it, the breechblock is free and the recoil spring will drive it forward to chamber a cartridge.

On each successive pull of the trigger the hammer will be released to strike the firing pin and discharge the cartridge in the chamber. The barrel and breechblock will recoil until the barrel reaches its stop and is halted. At that point the locking block will be cammed down out of contact with its engagement notches in the underside of the breechblock.

The breechblock will then continue to the rear in its guide in the barrel extension carrying the empty cartridge case held in the extractor in its face, seen at the top of the front of the breechblock. The case hitting the ejector will be hurled out of the pistol. The compressed magazine spring will force the cartridges up to bring the next cartridge in line for loading, the cartridge being held in place by a lip at the top of the magazine well. The rearward stroke of the breechblock will cock the hammer. At the end of the recoil stroke, the recoil spring will reassert itself and drive the breechblock forward to chamber a cartridge and snap the extractor into the cannelure in the cartridge case for extraction. When the trigger is released, its spring will move it forward far enough to effect contact with sear to permit release of the hammer for firing the next shot. Note that this model is semi-automatic in that a pull is necessary on the trigger to fire each individual shot. This is a very desirable feature as it prevents firing more than one shot on a trigger pull, thereby preventing accidents. A full automatic pistol fired from one hand is not a practical weapon, since it cannot be held effectively on a target.

Click here to purchase Mauser Rifles and Pistols in paperback

Return to Mauser Rifles and Pistols Table of Contents