The following information on the founding of Smith & Wesson comes from Smith & Wesson Hand Guns by Roy C. McHenry and Walter F. Roper. Smith & Wesson Hand Guns is also available to purchase in print.

The inventor who gets too far ahead of his time is not appreciated until long after he has gone to his reward. First plan for a practical steamboat was drawn by an inventor during the reign of Louis XIV, but instead of recognizing his genius, authorities placed him in an insane asylum. Faraday discovered the anesthetic power of ether, but it was more than a century later before a superstitious world permitted its use for the alleviation of operative pain.

A more recent case was that of Pauli, the Paris gunsmith. As early as 1812, Pauli was making a breech-loading, center-fire shotgun which employed a brass cartridge case. He was so far ahead of his time that it took the world 50 years to catch up with him, and today hardly anyone credits him with one of the great basic inventions in the world of firearms.

Of course, Pauli’s brass cartridge wasn’t a practical success for two reasons: First, he made his cases thick and rigid from base to mouth; Second, he failed to construct his primers so that they would fit their sockets gas-tight. Several years passed before other inventors discovered that the brass cartridge case had to be built with a thin-walled mouth which would expand under the pressure of pent-up powder gases and thus seal them for an instant within the bore. Such momentary expansion prevented the gases from escaping at the breech until the forward motion of the charge relieved the pressure. Once the pressure decreased the cartridge case contracted and could be extracted readily.

Discoverer of the tapered-wall cartridge was a fellow-countryman of Pauli named Pottet, who made and patented a center-fire cartridge with a gas-tight primer in 1839. It worked beautifully, but it had to be made by hand and the expense was prohibitive. Thus the manufacture of metallic cartridges on a commercial scale was delayed until a process was evolved for drawing brass by machinery, which was not for some years. By that time a third Frenchman, Houiller, had patented a different type of cartridge, the pin-fire, which operated by exploding the primer with a pin inserted at the side of the cartridge base.

Houiller’s patent was granted in 1846 and in the early 1850’s an Englishman named Lang produced a shotgun using the Houiller ammunition. The breech-locking mechanism of this weapon was extremely complicated, and it had a crank-operated extractor which did not add to its beauty. Of all the British sportsmen who examined the Lang invention, only T. H. Walsh, who wrote articles for the sporting magazines signed “Stonehenge,” saw any merit in it. The others ridiculed it unmercifully.

Writing under the name of Frank Forrester (his real name was Henry William Herbert), another Englishman who came over to this country about that time and produced several books on guns and hunting, made the following devastating comment:

“Stonehenge gives a cut and description of a new breech-loading double gun invented by a Frenchman, and improved by Mr. Lang, in which the barrels are raised from their connection with the false breech, by the turning of a crank, and expose the lower end of their caliber for the reception of a cartridge containing in itself, the percussion cap, the powder, and the charge of shot, with a small brass pin, impinging on the percussion powder, attached to it, which, when the loaded barrels are again brought into their proper position and connection, stands up in a notch between them and the false breech made to receive it, and meeting the blow of the striker, discharges the gun.

“Stonehenge speaks of this gun in terms of strong praise, and states his opinion, that ‘if as good in practice as it appears to him theoretically perfect, the invention will be almost as great an era in gunmaking as that of the detonator itself.’

“This language and praise are to me alike inexplicable. This gun has no nipple, no possibility of being loaded or fired except with the identical cartridge prepared for it, which, is, and can be, only prepared at the shop which supplies the gun. It is true, he says, that the cartridge cases remain in the gun, and on the withdrawal can be recapped and recharged many times, but, apart from the inconvenience of lugging about on your person a hundred or two, if you expect a good day’s sport, of these cartridges—since the idea of a sportsman sitting down in the middle of a snipe-bog or a cane-brake, to recharge the cartridges out of a powder-and-shot magazine, which he must carry about with him, is preposterous—what on earth is the shooter to do, if he takes it into his head to visit the Himalayas, or the Rocky Mountains, Canada, or the Cape, or any other distant shooting ground (by no means impossible to, or unattempted by British sportsmen), where cartridges for Lang’s breech-loading double-barrels certainly are not to be found growing on thorn bushes? Is he to carry with him, in heaven’s name, a hundred barrels of cartridges on camel-back, or mule-back, or on his own back, with the consciousness that these indispensables, once used up, his double-barrel is of less use, even, than a broomstick?

“The want of simplicity is enough to ruin any invention, and this, it needs no prophet to foretell, must be inoperative, except as a pretty plaything to be used at home.”

Mr. Forrester continues for another page, proving that he can reload his cap-and-ball scattergun as quickly as Lang’s, “by the muzzle with a good flask and Sykes patent-lever pouch.” He is generous enough to concede, however, that the system “might be applied to rifles with great advantage.” [From “The Complete Manual For Young Sportsmen,” Page 69.]

A few years after M. Pottet set out to market his invention, two men in England, by name, Hanson and Golden, were carrying on a series of dangerous experiments. Their objective was to make fulminate of mercury serve not only as a detonator—which had been done before—but also as a propellant for bullets.

The restive quality of fulminate and its vicious tendency to fly into a tantrum on the slightest of provocations are well known. It has potentialities several times the strength of gunpowder, and indeed its name is derived from the Latin word for lightning.

Hanson and Golden were fortunate enough to conclude their experiments with eyes, arms and legs intact and they actually produced a bullet with a hollow base containing the fulminate. It was to be used in a breech-loading gun which was to be discharged by “a needle striking at the base of the projectile.” They obtained a British patent on the hollow-base bullet in 1841, but never went to the trouble of designing a gun in which to shoot it.

Six years later another Briton, Stephen Taylor, came out of his laboratory with a projectile made along somewhat similar lines. His hollow-base bullet, however, contained ordinary gunpowder, “with the base of the projectile covered with a cap provided with a touch or match hole for igniting the charge by means of guncotton or other explosive matter.” Taylor gave more thought to the weapon to be used, for he says: “The projectiles are to be contained in a magazine consisting of a self-acting feeding tube, which is attached to the barrel of the piece, and as one projectile is discharged, another is to be pulled forward into the breech of the barrel and fired in succession.”

Taylor’s patent was granted in 1847, but nobody appears to have taken much interest in it until two years later, when Lewis Jennings “borrowed” his ideas for use on repeating rifles and pistols. Jennings was granted a United States patent on his hybrid invention, which was an improvement on a type of weapon which W. Hunt had patented a few months before.

The Jennings rifle and/or pistol had a tubular magazine containing the projectiles located under the barrel, but the bullets were fed into the barrel from below, and not from the rear as was contemplated by Stephen Taylor. A ringed trigger operated the loading mechanism and detonation was accomplished by use of a tape primer which had been invented by Dr. Edward Maynard. As Taylor’s was a British patent, he received no royalty for his contribution to the Jennings arms when Robbins and Lawrence, a gunsmith firm of Windsor, Vermont, began to produce them, but Dr. Maynard had to be given a cut on each transaction.

Fortunately, Dr. Maynard was not entirely dependent on his income from this source, because the Jennings repeater was a dismal failure. So much power was required to drag the long-geared bullet through the barrel that it emerged with little more alacrity than a pellet from a child’s pea-shooter. It was an ingenious weapon, but ingenuity was a poor substitute for deadliness in the United States of the 1850’s. It would have remained a collector’s curiosity if an inventive genius named B. Tyler Henry had not been working at the Robbins and Lawrence plant.

Henry’s employers probably were unaware that he had designed an improvement on the Hunt-Jennings-Taylor repeater by substituting for the ringed trigger a lever pivoted at the front of the trigger guard. When the lever was operated a fresh bullet was forced into the ·barrel and the trigger was cocked in readiness for the next shot. Although this refinement may not have improved the gun’s ballistics, it was an important step forward on the road to an effective repeating weapon.

Like a good many geniuses, Henry lacked money for a patent search, application and final fee, so he took a few days off and went down to Worcester, Mass., where he had formerly worked in one of the gunsmith shops which flourished in the town. There he located Horace Smith, one of the finest artisans of the gunsmithing trade, who was rifling barrels for the well known firm of Allen, Brown & Luther.

Perhaps it was not strictly ethical, but he told Smith that the Jennings rifle was about to be discontinued because of its failure to perform up to specifications. It could be bought up for very little, he thought, and with his improvements might be developed into a very profitable piece of merchandise.

Sometime subsequent to this conference, Horace Smith applied for a patent for a “Magazine Firearm” and received his final papers under date of August 26, 1851. These patent drawings show a rifle bearing a close external resemblance to the Jennings arm, including the tubular magazine under the barrel and the ring trigger. However, considerable difference is noted in the interior details. Eliminated was the notched rack whose forward end acted as the magazine gate, and substituted was a wedge-shaped breechblock which narrowed in the direction of the butt. The muzzle end of the breechblock was depressed (somewhat after the manner of that in the later-developed Peabody and Martini actions) by a link action of the ring trigger, and moved backward, so that the hollow-base bullet was thrust backward under impulse of the magazine spring, and then upward, when a forward motion of the ring trigger inserted it in the chamber of the rifle and closed and locked the action. Although it seems obvious that the invention was at least partly the work of B. Tyler Henry, his name does not appear in the patent papers.

The patentee seems to have taken no steps toward putting his device in production. Mechanical difficulties may have developed, though the design appears feasible enough on the patent drawing. More likely, Horace Smith had exhausted his capital in obtaining his patent and was obliged to look about for another investor, whom he found sometime between the years 1851 and 1854 in the person of Daniel B. Wesson. Thus was begun one of the great units of the American firearms industry and a backward glance is needed to establish the identity of this new partner.

Wesson was a younger brother of Edwin Wesson, inventor of the Wesson-Leavitt revolver, with its hand-turned cylinder, which was manufactured in the period following the failure of the Paterson Colt Corp. and the comeback made by Colonel Colt at the time of the Mexican War.

The elder Wesson had died about 1850, leaving to Daniel B. Wesson and other heirs a patent application for an improved revolver with a mechanically-operated cylinder. Later events proved that he also bequeathed them the ingredients for one of the most celebrated law suits in firearms history.

Having received a patent for Edwin Wesson’s improved revolver, his heirs formed the Massachusetts Arms Company and began the manufacture of hand guns which had several desirable features. One was a frame which pivoted upward just forward of the hammer, permitting quick removal of the cylinder for reloading. In some respect it was better than the system employed by Colonel Colt and the latter immediately brought suit for infringement of his basic patent on mechanically-revolved cylinders. Colonel Colt conducted his case in a manner thoroughly in keeping with his reputation for sportsmanship. He made no demand for damages, but simply put to the court the question as to whether the Massachusetts Arms Company’s revolver was an infringement.

To the trial of this celebrated case was brought an imposing array of legal talent. As his counsel, Colonel Colt retained Edward S. Dickerson, foremost patent attorney of his time, while the Massachusetts Arms Company employed one of the most noted trial lawyers of that era, the Hon. Rufus Choate. In the end, the patent attorney won out over the general practitioner and the Massachusetts Arms Company was deterred thereafter from making revolvers under the Edwin Wesson patent.

We may safely assume that the defeat rankled in the bosom of young Daniel B. Wesson and that he promised himself and his family economic vengeance at the earliest possible moment. He couldn’t get back into direct competition with Colonel Colt until the Colt patents expired, for the decision was sweeping and upheld Colt’s exclusive right to manufacture weapons with mechanically-revolved cylinders. But the patents had only a few years to run and after that they were everybody’s property.

Meanwhile Daniel Wesson was chafing at the bit. Doubtless he had some money of his own and doubtless also he was acquainted with Horace Smith—perhaps with Tyler Henry. At any rate, the three of them got together and Wesson was introduced to the possibilities of the Jennings repeater. It suggested a profitable interlude while waiting for the Colt patents to expire, so Wesson decided to join the firm.

See them now, bending over a drafting table under a smoky sperm-oil lamp, or fitting the action of an experimental gun. Which of the three evolved particular features of the new design is unknown today, but presently another patent application was on its way to Washington bearing the names of H. Smith and D. B. Wesson. (Tyler Henry seemed destined to remain a silent partner.) After the usual delay on the part of the patent examiners, the new patent was allowed on St. Valentine’s Day of 1854 and the firm of Smith & Wesson became an actuality.

Like the previous patent obtained by Horace Smith, this one was labeled “Magazine Firearm.” Although the official drawing was of a pistol, the system could be—and was—applied equally well to shoulder arms. Some of the features of the Horace Smith patent were utilized, but the new design went several steps further. The link arrangement which fed the bullet-cartridges from the magazine into the chamber had a neat “elevator” attachment which did the job more efficiently. In place of the ring trigger was a lever formed of the trigger guard—not unlike the original improvement made by Tyler Henry. Pivoted forward of the trigger, this lever operated the loading mechanism and in the same motion shoved back a long, cylindrical breechblock, working in direct line with the axis of the bore, which pushed back and cocked a centrally-set hammer. The front of the breechblock was formed into a firing pin extending inside the chamber.

The original Jennings arm had employed the Maynard tape primer, but an examiner familiar only with the percussion cap system could not have learned from the Smith-Wesson drawings how ignition was to be effected. Truth was that the partners had employed the Hansen-Golden system, previously described. Each bullet had a hollow base in which was placed a small lump of fulminate of mercury. This temperamental compound supplied ignition by detonation, when the shock of the hammer was transmitted through the breechblock-firing pin, and propelled the bullet as well.

It was the same system that was used in the needle guns of the Germans and the French Chassepots, except that the latter had the added advantage of a powder charge set off by the fulminate at the base of the bullets. There was no need for an extractor, for the cartridge formed the tail of the bullet and went out of the barrel.

A clause in the patent specifications, however, indicates that the partners had in mind from the beginning the adaptation of their arms to the use of metallic cartridges. The specification is so obscurely worded as to defy rationalization, and as far as can be ascertained no attempt was made to shoot metallic cartridges in any Smith & Wesson lever-action pistols or rifles. Tyler Henry perfected the idea later in the rifle that bears his name, but he was no longer with Smith & Wesson.

Soon after the patent of February 14, 1854, was granted, the new firm established itself in business at Norwich, Conn. Tyler Henry was not a partner but he was made superintendent of the plant, a position which he may have thought would be more profitable than a membership in the firm. If so, his pessimism was groundless, because the Smith & Wesson repeater was popular from the very beginning.

There are no indices today to give us the scale of the young firm’s operations. No payrolls are extant, no records were filed with the Treasury Department for tax purposes, and of course Social Security was nearly a century in the offing. One thing, however, we know without question: From the first gun turned out at the Smith & Wesson plant in Norwich, only the best craftsmen were employed to fashion their rifles and pistols. Any collector who is lucky enough to own one of those old guns will tell you that—with a little oiling and cleaning—it will still function smoothly and its trigger pull will compare favorably with a modern Smith & Wesson. Throughout its history the firm has never receded from the high standards of workmanship it set at the beginning.

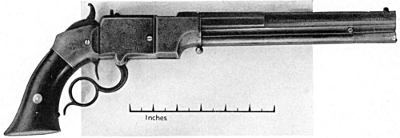

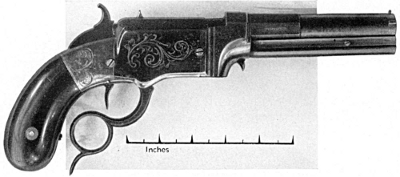

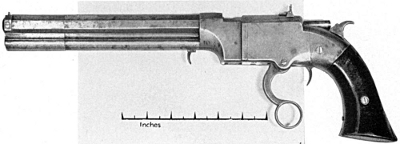

The popularity of those old repeaters is easily explained. They had not only the benefit of craftsmanship, they had eye appeal. All exposed metal parts were blued except the hammer and trigger; stocks were of rosewood or ebony, “piano finished;” and the arms themselves were graceful and well balanced—although, like most of the early hand guns, they were small for the average hand.

The weapons were loaded at a point near the forward end of the magazine tube. There the tube was cut through and a sleeve formed around it containing the magazine spring, which was compressed and held with a catch while the bullet-cartridges were inserted, base down. When the tube was filled the sleeve was turned until it was in alignment with the rest of the tube and the spring was released to apply pressure upon the line of bullets.

These bullets, containing detonator and propellant all in one mixture, were cylindro-conoidal in shape, with the points cut flat to minimize the danger of setting off the adjacent cartridge. As an additional safeguard, a pierced cardboard disc was glued to the base of each cartridge. Magazines of the longer barreled rifles held as many as 20 shots, while the pistols held 8 to 10 charges each.

Rifles and pistols were made in three calibers, a .44, a .36 and a .31, perhaps in imitation of the most popular types of Colt revolvers. Students of old firearms are aware that these calibers did not originate with Colt. The .44 in a round ball runs approximately 50 to the pound; the .36 100 to the pound; and the .31, which comes close to measuring .32, 150 to the pound. The Allen Pepperbox, patented in 1837, was made in .31 caliber and the Allen single-shot, double-action pistol with the flat-top-hammer shot the same sized ball. Colt did not adopt the .31 caliber until after the Mexican War and the .36 Navy came out in 1851. All three calibers have come down unchanged to the present time—in name, at least. The .44 is still a .44, though slightly shrunk; the .36, similarly reduced, is known as a .38; and the .31 now calls itself a .32.

Smith & Wesson wisely refrained from attempting to duplicate the thundering charge of the Dragoon Colt in their .44 pistol. Fulminate of mercury may be made to behave in small charges, but as the load increases the compound’s unpredictability advances in the same ratio. In quantities which the partners were obliged to use in the largest bullets, it was quite capable of blasting the walls of the chamber instead of speeding the bullet out of the muzzle. Daniel B. Wesson acted as ballistician for the firm and undoubtedly was well acquainted with the nature of the explosive. In addition, he knew that the breech mechanism was not overly strong and that its safety factor was dangerously low. Therefore, it behooved the firm to stick to “varmint rifles” and pocket and belt pistols as long as they used this tricky substance.

There is no reason to suppose that Smith & Wesson publicized the undesirable features of their arms. Probably they prayed silently that no accidents would mar its popularity, and there are no records of any disasters having occurred. Old-time shooters who used the repeating arms complained that they had an unpleasant habit of letting go with all the cartridges at one time, but this trait was not confined to the Smith & Wesson. It was not at all unusual for the Colt percussion revolvers and rifles to let go with a salvo, particularly if they had been carelessly loaded. Round-ball ammunition was more often the cause of this frightening display than cylindrical slugs, since the flame of the discharge could leak much more readily around the circumference of the ball.

But the danger of chain ignition was not the only trouble Smith & Wesson encountered with their new weapons. Soon after they began to manufacture their magazine arms they discovered that the fulminate of mercury used in the bullets left a violently corrosive residue in the barrels. Cleaning practices of that day consisted of running a rag down the barrel at the end of a wiping rod and, perhaps, swabbing it out with water after the day’s shooting was over. When dry, a coating of some animal oil may have been applied—bear grease and deer fat being considered the best.

Moreover, observant owners of Smith & Wesson rifles and pistols saw the laws of erosion taking their toll in the bores of their guns. Where there had been regular grooves and lands, there were now gulches and coulees and they literally couldn’t hit a flock of barns with them. While this was not altogether surprising—muzzle-loading guns as a rule being subject to the same wear and tear—there was a difference. The muzzle-loaders could be rebored several times, each time a little larger, but the Smith & Wesson had to have a new barrel. Any one of these defects was not critical in a time when all firearms possessed some imperfections, but in the aggregate they were serious. The partners called in Tyler Henry and the consensus was that something had to be done.

Once again Daniel Wesson retired to his laboratory and worked at his experiments until late at night amid the stink from the sperm-oil lamps. A keen observer of gun developments abroad as well as in this country, he had learned recently of the “bulleted breech-caps” which a Frenchman named Flobert was producing and which were reputed to be popular for target arms. These were small, cylindrical cases of copper, containing fulminate, with a round ball projectile, and they instantly called to his mind the unused specifications about an extractor for their repeating guns as mentioned in their patent.

Recollection of a still earlier cartridge patent sent him searching through his foreign and domestic patent office reports, and finally he found what he was looking for—the 20-year-old Pottet shotgun cartridge patent issued in France.

With this as a starting point he returned to his experiments and a week or so later called in Horace Smith and Tyler Henry to show them what he had developed.

On the bench before him lay what appeared to be one of their standard .31 caliber pistols, but instead of loading it in orthodox fashion, Wesson produced a copper cartridge and held it before them.

“You see, fellows,” he said, “it works this way. This case has powder in it, but underneath is a little cup like a percussion cap, set in the middle of the base. Inside it is a small piece of metal, on top of that is a flake of fulminate, or you can use chlorate of potash if you’d rather. On top of that is another bit of metal and the powder is crowded down on top of that and almost fills the case, with just room left for the bullet.”

He fitted the cartridge in the pistol and continued: “Now when I set it into the chamber, where it fits pretty tight, and close the breech, the plunger will give it a peck when I pull the trigger.”

The gun spoke with authority.

“You see,” said Wesson, “I hit the mark, too, at twelve yards. What do you think of it?”

Horace Smith was impressed but skeptical. “How long did it take you to make the contraption?” he inquired.

“Dang near two days,” Wesson confessed. “Course we could make a die and stamp the shells out of copper sheet when we got to making them in quantity. But it’s quite a job to set the little cup in the base and fit in the two pieces of brass—anvils, I call ’em. That’s what took the time.”

“Pretty neat,” remarked Tyler Henry. “It won’t do, though, ’cause it costs too dang much to make ’em. No coppersmith, no matter how slick he is, could turn out mor’n a dozen a day. Leavin’ out the cost of powder and lead, who’s goin’ to pay a day’s wages for a dozen cartridges?”

“Waal,” contributed Horace Smith, “some time we might figure out a machine that would do the coppersmithin’ job and then we’d have something real. Meanwhile, Dan’l, we’d better make sure of what we’ve got. S’pose you fix up a drawing and send it down to them Washington patent lawyers—same ones that fixed things up last time. We can afford to sink a hundred or so in the idea, even if we never use it. You keep on, though, and see if you can’t figure out a ca’tridge that’s easier to make.”

Wesson sent his drawings to Washington promptly, but the patent proved elusive. The lawyers objected that his cartridge was similar to the Pottet shotgun shell and also to the metallic cartridge invented by Dr. Maynard, which was ignited by an outside primer. Not until a lump of beeswax, to provide lubrication, was placed between the powder charge and the bullet, would the patent office concede any originality to the idea—and then only as an improvement on the Pottet and Maynard systems. So Daniel Wesson went back to his experiments.

Not long thereafter a meeting was held quite different from that at which the partners had discussed the shortcomings of the Smith & Wesson repeating arms. In addition to Smith, Wesson and Tyler Henry, there was a fourth principal—a man of middle age whose broadcloth pantaloons (they were lined in those days and referred to as “unmentionables”) stood out so stiffly they threatened to creak when he walked. His name was Oliver D. Winchester. He was a shirt manufacturer from New Haven, a former governor of Connecticut and rumor had it that he could write checks in six figures—which didn’t “bounce.” At a table on the other side of the room, flanked by an imposing array of legal documents, were two lawyers. Tyler Henry was making slow work of one of the legal papers with the aid of a pair of iron-bowed spectacles.

“Well, Governor Winchester,” said one of the lawyers, “everything seems to be in order. All three of the repeating arms patents are assigned in proper form and the bills of sale with attached inventories have been checked over. All that you have to do now is to pay down the purchase price and take over the plant—lock, stock and barrel, as my friends in the gunmaking trade might say.”

“All right,” said Mr. Winchester, “I believe Mr. Smith wished the payment to be made in specie. Here it is.”

He reached down and lifted a pair of canvas bags with considerable effort.

“Hold on a minute,” said Tyler Henry. “I’ve been readin’ this here contract and it don’t say a word about them ca’tridges you fellers are gettin’ a patent on. How about that?”

“I declare,” said Horace Smith. “I clean forgot about that detail.”

“You told me,” said Henry, “that if I found a buyer for you, you’d give the new concern the right to make ca’tridges under any patent you have or may take out later on, to use in the pistols and rifles they’re goin’ to make. Ain’t that so?”

“I believe we did discuss some such point as that,” admitted Horace Smith. “It slipped my mind.”

“Then it ought to be wrote into the contract,” declared Tyler Henry.

“If there was any such understanding, it certainly should be embodied in the agreement,” said the other lawyer, who represented Winchester.

Followed a ten-minute silence while one lawyer scratched away with a pen and the other studied what he had written.

“This ought to cover the matter,” said Winchester’s attorney: “And it is further agreed and understood, by and between the parties hereto, that the parties of the first part (he nodded toward Smith & Wesson) shall permit the party of the second part (that is you, Mr. Winchester) to manufacture and vend metallic cartridges suitable for any and all repeating-arms made under the patents hereinbefore described and heretofore assigned to the party of the second part, at his, said second party’s own proper cost and expense: but free from any royalties or other charges which might be made for such manufacture, by reason of the rights of the parties of the first part in or appertaining to any patents upon metallic cartridges, which said parties of the first part may now own or which they may hereafter obtain.”

“I don’t see the use in goin’ through such a long rigmarole,” remarked Tyler Henry, “but I guess it fills the bill.”

Within a few days the machinery of the Smith & Wesson shop, which had been used to make repeating rifles and pistols, was moved down to New Haven and the handful of men who had been employed to make them had taken up lodgings there. Articles appeared in the New Haven papers which told of the formation of the Volcanic Arms Company, headed by O. D. Winchester and Tyler Henry.” [“When Smith & Wesson and Oliver Winchester came to terms on the purchase price, there was a gentlemen’s agreement entered into that was verbal, but has never been violated by either company in their many years of active existence. Oliver Winchester pledged that his company would never compete in the revolver business by manufacturing them; likewise, the Smith & Wesson Company agreed never to produce rifles. And this agreement has been recognized by each succeeding generation—having proved more binding than lots of contracts that were elaborately drawn and legally perfect.” From “Encyclopedia of American Hand Arms,” Page 249.]

Horace Smith and Daniel B. Wesson likewise had deserted Norwich, but they had gone north instead of south. With a financial backlog reposing in a Springfield bank, they rented modest quarters where they could continue their experiments with cartridge revolvers.