The following information on the Smith & Wesson American Model comes from Smith & Wesson Hand Guns by Roy C. McHenry and Walter F. Roper. Smith & Wesson Hand Guns is also available to purchase in print.

Not until after the surrender of Lee in May of 1865 did Smith & Wesson have occasion to print a new catalogue. It announced that they were prepared to fill orders for what they called their latest improved Model 1 1/2, which was a five-shot pocket arm with a 3 1/2-inch barrel chambered for the .32 short rim fire cartridge instead of the .32 long.

In this one tip-up model, they discarded the cylinder stop on the top strap and installed one inside the bottom strap such as was used by most other makes of revolvers. However, they were not yet ready to discard the weak and faulty tip-up barrel, hinged to the front of the top strap and latched to the front of the lower strap, although it precluded the use of cartridges larger than the .32. This model had a plain cylinder and square butt and 25,224 were made before it was taken out of production in 1868. The six-shooter Model 2 was continued without interruption until 1874.

In February, 1868, Smith & Wesson decided that the earlier .22 left something to be desired in appearance and brought out their Third Model. Internally, it was the same as the Second Model, but externally it had been streamlined by rounding the octagon barrel and eliminating metal in the barrel base. The cylinder was prettily fluted after the fashion made popular by Colt, but greatest change was in abandonment of the square butt and revival of the old birdshead grip of flintlock days. Colt expressed indirect approval of the change by copying the grip for its early cartridge revolvers.

The Third Model’s life span was longer than either of the earlier models, as it was manufactured until 1879 and was the last of the tip-ups to be made. Altogether, 128,528 of them were made. They were sweet shooting little guns and many a young chap learned the trick of aim and trigger-squeeze with them.

In January, 1869, Smith & Wesson played their last card in the rim fire game, over and above their .22 caliber. This was a New Model 1 1/2 .32 and was really a slight enlargement of the birdshead grip .22. Although designed to use the .32 short, which came into popularity about that time, it would also take the .32 long cartridge without special chambering. In this model, the top strap cylinder stop appeared once more and there still was no safety notch on the hammer. You had your choice of blue or nickel finish. 93,280 of them were made before the model was called in, in 1875.

The date of 1869 has been mentioned as important in the history of Smith & Wesson, due to the fact that the Rollin White patent expired in that year. Shortly before this occurred, and while rival manufacturers were tooling their plants in preparation for the open season on cartridge handguns, Daniel B. Wesson took another trip to Washington.

This time he was in an entirely different frame of mind, as the business in hand was acquisition of a couple of patents which the partners believed would keep them a lap ahead of the field in spite of the lapse of the White patent. One of these assignments was obtained from W. C. Dodge and the other from C. A. King.

Of the two inventors, Mr. Dodge was probably the more impatient to sign on the dotted line and get his money, for he had waited since 1865 to market his patent. It involved the opening of the frame at the rear of the cylinder and the pivoting of the barrel assembly at the front of the lower strap. While this feature was partially covered in the expired patent of the Starr Arms Company, taken out on January 15, 1856, Mr. Dodge had perfected a neat latch to fasten the top strap securely to the frame as an improvement on the slow and clumsy screw arrangement of the Starr patent.

Mr. King’s patent was a genuine innovation, since it provided a system for the simultaneous ejection of empty cartridge shells—one of the principal problems with which inventors had wrestled since introduction of the metallic cartridge. Like so many novelties, the King invention was complicated and differed considerably from the system used on later top-break revolvers. It operated by means of a cogwheel enclosed in the hinge joint and a small plunger set into the end of the lower strap. When ejection was completed, a cam was released which retracted the rack so that it was flush with the cylinder wall, permitting reloading and closing of the action. Through a process of simplification which extended over several years, the cogwheel and plunger eventually were eliminated. The Dodge and King patents dovetailed so perfectly that it seemed the two inventors must have worked together on them.

When Smith & Wesson produced their first batch of revolvers under the new patent combination cannot be determined accurately, but it probably took place between August 24, 1869 (when the King patent was issued) and the first of the following year.

This new product of the brains of Dodge, King and Daniel B. Wesson was a hand gun for which none of the contributors had to apologize. Also, it was the first large-caliber revolver designed to shoot metallic cartridges. It is true that a number of cap-and-ball guns had been altered surreptitiously and adapted to the Henry rim fire .44 and similar cartridges by substitution of a bored-through cylinder; but the bore of these hybrids was generally larger than the bullet diameter and they were not noted for their shooting qualities.

The new S&W resembled the 1860 Colt in outline and balance, and was of approximately the same weight. Its eight-inch barrel was too long, perhaps, for a quick draw, but barrels ran to length in those days. This model departed from previous S&W practice in that it had a bow-shaped trigger guard, a safety notch and half-cock. A rib ran the full length of the round barrel and a notch in the center of the barrel catch formed the rear sight. As previously mentioned in the description of the Dodge patent, barrel and frame were joined at the front of the bottom strap. Although it was called a .44, the actual caliber of the bore was .429 and the rifling was right-hand twist, one turn in 20 inches, which has remained standard for large bore Smith & Wesson arms ever since.

The American Model, to use the name it acquired through the years, was a six-gun and the cylinder was handsomely fluted—not only for appearance but also for elimination of needless weight. Ordinarily it was supplied in the famous S&W blue, but the nickel-plated model was available for those who wanted it.

Not all the improvements in the new arm were in the gun itself. The cartridge was developed on the Berdan system—center fire with outside primer—and the brass case was greatly superior to the copper cases previously used. The powder charge, weight of bullet and resulting ballistics were about the same as those of the percussion Colts and Remingtons in the same caliber, i.e., 25 grains of powder and 218 of lead, with a muzzle velocity of 650 f.s. and 200 ft. lbs. of energy, according to Colonel Hatcher’s figures. Lubrication was on the outside. This cartridge still goes by the name of “.44 Smith & Wesson American.”

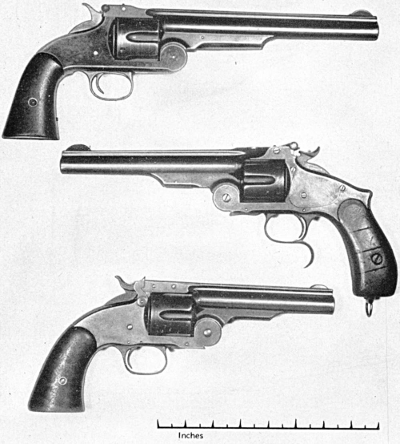

Smith & Wesson, single action, .44 Russian Military (First) Model Revolver, .44 S&W Russian center fire cartridge.

Smith & Wesson, single action, .45 Schofield (Second Model) Revolver. Also mode with eight-inch barrel, .45 S&W center fire cartridge.

The bullet had a rounded nose, which we know now does not communicate as great a shock to the anatomy as a flat nose, and it was cast with a shoulder slightly smaller than the bore to get it inside the neck of the shell—the latter having the same outside diameter as the bore. Developed years before for percussion revolvers, the shouldered bullet probably caused gas cutting to some extent. But while it was not designed for extreme accuracy, the arm will do very respectable target shooting up to 50 yards. Years later, Mr. A. C. Gould wrote in his “Modern American Pistols And Revolvers” (copyrighted in 1888):

“The old American Model Smith & Wesson revolver was a great favorite with those who knew what weapon to select for reliable work. Many are in use today, and highly valued as very accurate weapons.”

The feature of the new model which appealed to everyone instantly was that of simultaneous ejection, in lieu of detaching the cylinder and punching out the empty cartridge cases one at a time.

Soon after its introduction, the American Model won second place in tests held by the Ordnance Board of the War Department. That it did not fare better seems to be a reflection on the intelligence of the Ordnance officers rather than on the merits of the Smith & Wesson, for first place went to the Remington-Rider rolling block single-shot pistol. While the accredited winner chambered a metallic cartridge of knockout size, it was nothing but a glorified “hoss pistol,” and it was fortunate for Uncle Sam’s men of that period who packed the Remingtons that the “Injuns” behaved themselves.

One fortunate cavalry regiment, however, was equipped with the S&W American .44 and orders for the weapon began to be received from civilians all the way to California. The exact number of this model manufactured by the firm will never be known, due to some unexplained loss of records at the plant, but the figure must have ·been large.

Smith & Wesson didn’t fret long over defeat of their American Model in its encounter with the Remington “hoss pistol.” A U.S. government contract rarely involved more than a few thousand weapons, and the partners were about to consummate a deal which would make such a transaction look puny.

This contract involved a certain foreign power which had had previous dealings with American arms manufacturers. A year or so before, this particular government had contracted with General Hiram Berdan for several hundred thousand of the rifles patented under his name and shooting the ammunition he had invented. To digress for a moment, the Berdan rifle was a single-shot built on the trap-door principle utilized in the Springfields of that day—except that it had a straight-line firing pin working through the breech block, which was struck from behind by a spring-propelled bolt. More sensational than the arm itself was the bottle-necked cartridge of .42 caliber fitted with an outside primer, first of its type to be developed. (As already mentioned, the .44 S&W American cartridge was sired by the Berdan .42.)

General Berdan, who commanded the 1st U.S. Sharpshooters in the Civil War, had no facilities for manufacturing his rifles, so he licensed the Colt Corporation to fill the big foreign order and they both made a lot of money.

Now, to get back to the Smith & Wesson, it had been previewed by this same foreign power before the general public or even the Army Ordnance Board had seen it. Coded cables which in themselves amounted to tidy sums crossed the ocean between the foreign capital and the military representatives of that government in this country.

In 1870, with this important buyer still undecided, Horace Smith sold out to his partner but allowed him to continue the firm name. And right on the heels of the partnership dissolution came word that his Imperial Majesty, the Czar of all the Russians, had graciously decided to equip all his cavalrymen and artillerymen with modern revolvers (a little matter of 200,000 weapons) and would Smith & Wesson please hurry up and fill the order. There were a few difficulties connected with the windfall, such as slight changes in the frame of the American Model to suit the Czar’s whims, but these promised to be minor.

Springfield hotels were hosts to a great influx of guests during the next few weeks—guests who wore fancy uniforms, sported highly trained whiskers, and spoke a dubious kind of English. The younger ones were quite popular with the pretty girls of the town. Rumor said they were all titled Russians, yet they insisted on wearing their gaudy uniforms into those sections of the Smith & Wesson plant where the dirtiest jobs were under way—with disastrous consequences.

In spite of these eccentricities, which were accepted good naturedly by the workers and citizens of Springfield, executives at the plant found that the visitors were not at all ignorant of mechanical operations. And Daniel Wesson discovered at the first conference that they had definite ideas of what a military revolver should be.

In exterior design, the Russian officers had been influenced to some extent by contemporary English revolvers. They didn’t appreciate the streamlined frame of the American Model and insisted upon incorporation in the grip of an angular knuckle which the British called a prawl. This extrusion on the back of the frame is designed to keep the hand of the shooter from sliding upward above the grip, but in accomplishing its purpose it digs into that tender part of the hand between the thumb and forefinger and after a couple of dozen shots the shooter is ready to quit and go home. When the prawl is wide, as in the .38 and .45 Colt automatics, it is not so uncomfortable; but on the Russian Model it is less than half an inch in width and it must have tortured those soldiers of the Czar who had to use it every day.

Of plain walnut and unchecked, the stock of the revolver was rounded and more slender than that of the American Model. The bottom of the stock was flattened to receive a lanyard swivel, desirable adjunct to a military weapon. Length of the barrel was reduced to 6 1/2 inches for quicker drawing, but this was really an improvement on large caliber American revolvers of that period, all of which had barrels of about 8 inches. The interior mechanism of the American Model seems to have given the Russian officers no concern, for they left it without change.

Whether the alterations in the exterior design had given the Russians an improved weapon is open to doubt, but the same cannot be said for the type of ammunition they specified. In that department, some unknown and unsung Russian ballistician did a really magnificent job and turned out a cartridge that was far superior to the original .44 S&W American.

This smart chap argued that there was no particular reason why the cylinders should be chambered to the exact diameter of the bore, so he had them reamed to the extent of twice the thickness of the cartridge wall—amounting to approximately 1/100 of an inch. This change permitted use of a shell with an inside diameter of .429, same as the bore, and cancelled the need for a shoulder on the bullet. Next step was to crimp the open end of the shell around a groove on the bullet. Experiments with the new cartridge suggested to him that the bullet might be heavier, so he added enough length to the mould to make the weight of lead 246 grains—while at the same time cutting down the powder charge from 25 to 23 grains.

The results were surprising. Instead of lowering the velocity by increasing the lead and reducing the powder, he actually stepped it up to 750 f.s., 100 more than that of the American cartridge. This seeming paradox is explained by the design of the Russian’s bullet, which had the same diameter at the base as the widest section. The American bullet was smaller at the base because of the shoulder which went inside the shell case, and hence lost much of the propulsive force of the explosion. Muzzle energy from the new cartridge was 316 ft. lbs., a gain of 116 over the original. (Figures from Col. Hatcher’s Textbook of Pistols and Revolvers.)

Our unknown Russian ballistician may have “builded better than he knew,” for chronographing instruments were yet to be invented. Machine rests of crude design had been in use as early as 1855, however, so he must have known that the new cartridge was much more accurate than the .44 American.

Total output of the Russian Military Model was 215,704, of which very few remained in this country and hence are rarely encountered today.* The contract was completed on schedule in 1875, which meant turning the revolvers out at the rate of 175 per day. [*Marked on the barrel in Russian characters.]

Hardly had the Russian cavalry turned in its old single-shot percussion pistols and become accustomed to the new revolvers, when the Czar went to war with Turkey. Hostilities began in 1877 and terminated in 1879 in favor of the Russians, although the Turks were accounted good fighters. The Russian cavalry figured in many of the war’s important encounters, and undoubtedly some of the officers reported at length on the performance of the Smith & Wesson revolvers for the information of the Russian high command. But the Bolshevists had no more respect for war office records of the Czarist regime than they had for the Czar himself, so they probably burned them in lieu of better fuel when the revolution swept over Russia. Evidence that the Turks were impressed by the new revolvers is found in the fact that they sent in an order for Smith & Wessons while the war was still in progress. Delivery was not made, however, until after peace had been declared.

A second type of the American Model came out while the Russian revolvers were being produced, but no record of the number manufactured is available. This lot differed only slightly from the original type, the principal variation being in the design of the hammer. The original hammer carried a slot across its face above the nose which engaged a lug on the barrel catch, preventing release of the latter except when the hammer was at half or full cock. This feature was discarded in the later type because of its inconvenience and the delay in operation which it caused.

The Turkish Model alluded to was identical with the original American Model, save that it was adapted to shoot a .44 rim fire cartridge, no longer manufactured, resembling in its ·ballistics the Henry rifle cartridge. The hammer of the Turkish Model had to have a rectangular nose and a correspondingly rectangular slot in the frame to receive it. The barrel was 6 1/2 inches long and a total of 5,461 were manufactured. Hardly any of them are to be found in this country, although now and then somebody reports having run across one in the Levant. They can hardly be mistaken for the American Model, because the inscriptions on them are in Arabic—which resembles shorthand as much as it resembles anything.