The following information on the Smith & Wesson double action mechanism comes from Smith & Wesson Hand Guns by Roy C. McHenry and Walter F. Roper. Smith & Wesson Hand Guns is also available to purchase in print.

To most shooters the outstanding mechanical feature of the modern Smith & Wesson is the front support for the extractor rod—a construction designed to keep the cylinder in more perfect alignment with the barrel, and also to prevent damage to the rod should it receive a blow. The arrangement is at least theoretically sound. It is, however, only one of many differences between the S&W and the Colt which make a study of these two guns decidedly interesting.

While the number of parts of the Smith & Wesson probably exceeds that of the Colt, this is not in itself a disadvantage. In fact, the use of “double duty” parts often requires types of action which more than offset the gain made in eliminating pieces.

An example is to be found in the main and trigger springs and associated parts of the two guns. Both do the job perfectly, the S&W requiring five separate pieces to do the job which the Colt accomplishes with three. However, the two-armed Colt main spring is counted as one piece, while the S&W utilizes two distinct springs, each of simpler design. But the S&W springs are so arranged that pressures operate on them centrally, instead of on one side, as in the Colt. Results are almost identical, yet there can hardly be any question that the S&W designers, in adhering to the best mechanical principles at the expense of additional pieces, have produced a design more nearly in accord with the theory of pressure distribution.

In any double-action revolver, the sequence of operation is as follows: Starting from the “at rest” position of the hammer, to which it is rebounded from its extreme forward position, the first motion of the hammer toward the full-cock position must unlock the cylinder. This is true whether the hammer is actuated by pressure of the thumb on the hammer spur or by pressure of the finger on the trigger. As soon as this unlocking operation is accomplished, the pawl which rotates the cylinder engages a tooth on the ratchet attached to the cylinder, and, as the hammer is moved back, turns the cylinder sufficiently to bring the next chamber into alignment with the barrel. At this point the cylinder latch must drop into the next notch of the ratchet and lock the cylinder in place. Now the hammer can come to full-cock position, in single-action operation, or spring forward to discharge the cartridge if used double-action.

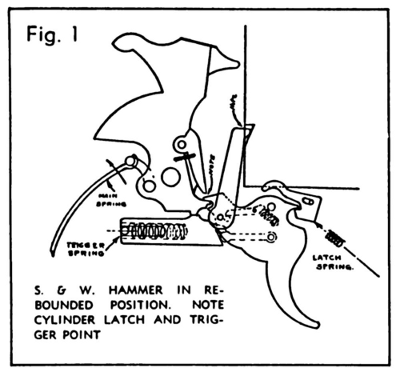

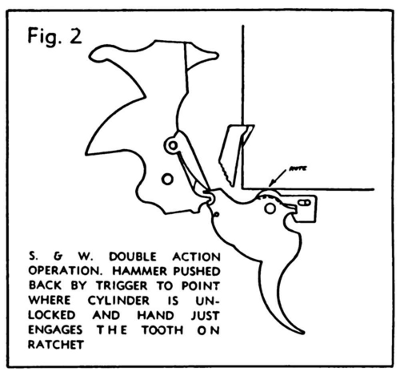

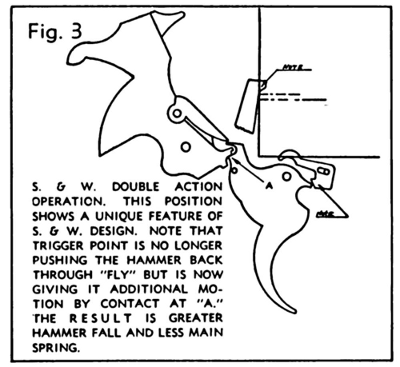

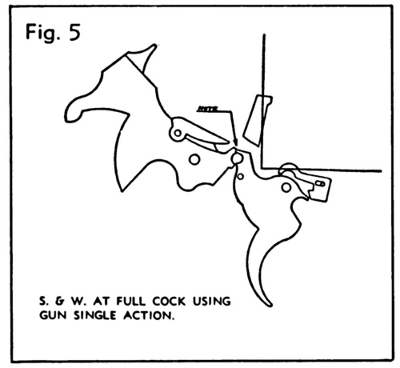

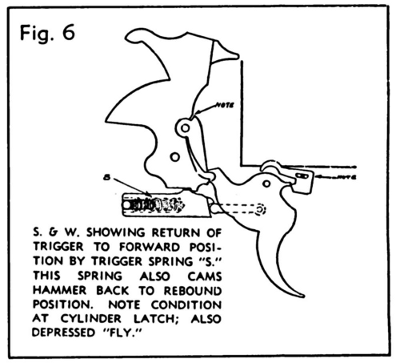

The shape of the Smith & Wesson parts, their location in the gun, and their positions at the critical points in this sequence of operations are shown in Figures 1 to 6. The following explanation will assist the reader in understanding just how they work:

For double-action operation, the parts are in the “at rest” position in Figure 1. It will be noticed that the front end of the trigger is engaged with the cylinder latch, the back end of the trigger under the double-action latch or “fly” on the hammer, and the cylinder rotating pawl somewhat below the surface of the ratchet tooth on the cylinder. Backward pressure on the trigger causes it to move to the position shown in Figure 5 and at once withdraws the latch from the notch in the cylinder, at the same time bringing the pawl into engagement with the ratchet tooth and the back end of the trigger into contact with the under surface of the “fly.”

In Figure 3 the trigger has been pulled further to the rear, and shows one of the fundamental differences between the S&W action and that of the Colt or other double-action revolvers. Notice that the back end of the trigger has pushed the hammer back as far as the fly will permit, but instead of releasing the hammer, the surface “A” of the trigger has come in contact with a special surface on the hammer so that still further backward motion of the hammer will take place before it is released to fire the cartridge. This extra motion of the hammer permits the use of a somewhat lighter main spring than would be needed if the shorter throw resulting from release from the “fly” were used, as in other guns. Note that the cylinder latch has been released and is engaging a notch in the cylinder so that it is locked in proper firing position, and the cylinder rotating pawl has turned the cylinder to its correct place.

Figure 4 shows the actual release point in the S&W when the arm is fired double-action, the gain in hammer motion being clearly illustrated if this drawing is compared with Figure 3. Note the position of the front end of the trigger in relation to the cylinder latch, also the over-motion of the cylinder operating pawl. This latter motion is made possible by allowing the pawl to slide past a flattened surface on the ratchet tooth, and serves to lock the cylinder in position more securely. Further movement of the trigger rearward will allow the hammer to fall, and as pressure on the trigger is removed the trigger spring forces the trigger forward to the position shown in Figure 1. Note that the trigger latch is slotted where the latch pin passes through it, so that it will remain in contact with the cylinder and not release it when the trigger presses it forward. This action is shown in Figure 6, just as the trigger is ready to snap into the recess of the cylinder latch, and just before the trigger point moves into the position shown in Figure 4 by slipping past the hammer fly, which it has compressed to permit its passage.

In Figure 5 the parts of the S&W are shown in the position they assume when the hammer is cocked with the thumb for single-action shooting. Note that an entirely different notch in the hammer is used and also that, due to the “double throw” of the double-action the total backward motion of the hammer is approximately the same as in single-action operation.

Reference to Figure 1 will show the type and position of the springs used in the S&W gun, all except the main spring being of the coil type. The trigger spring inside the rebound block does double duty, furnishing the power to cause rebounding of the hammer through the cam surface on the under side of the hammer, as well as forcing the trigger forward operating the cylinder latch and retracting the cylinder pawl across the ratchet teeth. Forward pressure on this pawl and its contact with the ratchet is maintained by a small spring inside the trigger operating through a small lever, also inside the trigger, on a pin in the hub of the pawl.

The rebound block of the S&W provides an almost positive hammer safety to prevent forward motion of the hammer if it is struck. However, due to the hammer’s distance from the center and the possibility of the parts springing under impact of a very hard blow, a second safety block is interposed between the hammer and the frame just below the hammer nose, or firing pin. This block is part of a spring lever which lies in a slot in the side plate of the gun. On its side is a cam surface which engages a similar cam surface on the cylinder operating pawl, so that when the hammer is drawn back for cocking, the block in front of the hammer is withdrawn. When the trigger is allowed to move forward after firing, at which time the hammer is rebounded by the block under its bottom, this lever again slips in between hammer and frame, thus making it completely proof against accidental discharge.

Earlier in this description it was stated that S&W design was based on central pressures, rather than side pressures, as with some guns. Study of Figure 1 will demonstrate to what extent this theory of design has been practiced. Note that the combined trigger and rebound spring is in a hole in the center of the rebound slide so that there is no sidewise pressure at all; also that the pressure of this spring acts on the trigger through a lever pivoted in the center of the trigger. The pawl and cylinder latch springs are arranged so that this same central location is obtained and they act on parts supported on both sides of the pressure point. Such construction eliminates any possibility of cramping, and while it may call for a few more parts, it will appeal to any mechanic as an ideal arrangement.

All operating parts of the Smith & Wesson are case hardened, a process which produces maximum strength and maximum hardness of wearing surfaces. In addition, the parts are ground and polished, and removal of the side plate reveals a mechanism like the interior of a watch which is a source of satisfaction to any lover of fine work.

Certainly, the modern Smith & Wesson continues the tradition established by the men who manufactured the first of these wonderful arms. Perfection of design, precision of workmanship and excellence of finish are as characteristic of today’s S&W as they were of these guns in the beginning. The company has kept abreast of developments through the years and today is better qualified than ever before to produce guns of quality that meet the every expectation of even the most critical shooters in both military and civilian life.