The following information on the Mauser HSc pistol comes from Chapter 36 of Mauser Rifles and Pistols by W. H. B. Smith. Mauser Rifles and Pistols is also available to purchase in print.

This is the last production automatic pistol designed by Mauser engineers before World War II halted their activities.

This arm uses the standard .32 Automatic Colt Pistol cartridge. The magazine holds 8 cartridges and another cartridge may be inserted in the chamber giving a capacity of 9.

The barrel is 3.37 inches long, the overall length is 6.5 inches, and the pistol weighs 20.6 ounces. The action is straight blowback, no lock being necessary in a weapon of this caliber and design.

This pistol incorporates a double action feature of general revolver type. Under this system, it is possible to carry the hammer down on a loaded chamber and to bring the pistol into rapid action by merely pulling straight back on the trigger. Through lever and spring arrangement, the hammer will be rotated to the rear and then slipped to hit the firing pin and discharge the cartridge in the chamber. The blowback or recoil will then force the slide back and cock the hammer for the succeeding shots in standard automatic pistol fashion. As in all automatic pistols, however, the firing chamber must be manually loaded for the first shot.

In all earlier forms of Mauser pocket pistols, whenever the chamber is loaded, the striker mechanism is at full cock. If an arm is carried this way, it is always potentially dangerous unless the thumb safety is kept applied. In periods of emergency, time may be lost in remembering to push the safety off. Another bad factor of this type of design is that if the weapon is carried ready for action, the striker spring is at full compression and may be weakened over a period of time.

With the double action feature, it is possible to carry the chamber loaded in complete safety with the assurance that the mainspring, not being under compression, will not be weakened. When it is desired to fire the pistol speedily, there is no necessity to think of safeties (though a thumb safety is provided to give double assurance to those desiring it). A pull on the trigger, as already stated, will fire the weapon without attention to any levers or buttons.

While the essential feature of this new Mauser pistol is the double action cocking system, it also represents a forward step in pistol development in the streamlining of design, in the shape and pitch of the grip which permits more instinctive pointing, and in the simplified takedown system.

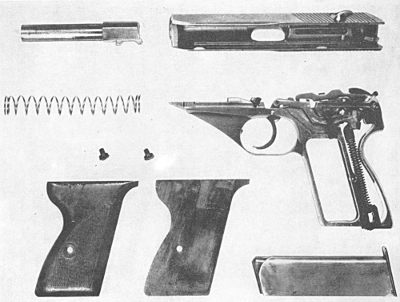

Parts of the Mauser HSc

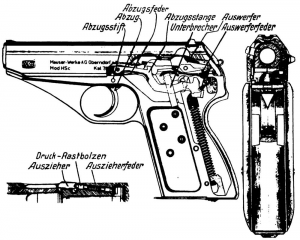

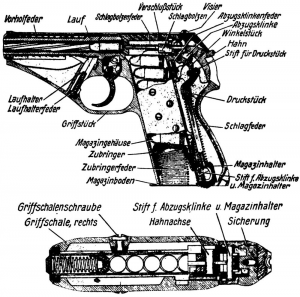

The principal parts of the arm are: The barrel, the slide whose rear section is the breechblock, the receiver which forms the grip and also houses the firing mechanism, the sights, the trigger mechanism and the safety. With the sole exception of the grips all parts are made of steel burnished for protection against rust. The grips are usually of plastic but may be of wood. (Note: Pistols made during the War were often poorly finished without burnishing).

The Barrel. The barrel forging is unusual. It is rifled with 6-grooves to the right. The rear chamber section is heavily reinforced and provided with an abutment against which the rear of the recoil spring, which is mounted concentrically around the barrel, is compressed. Two slanting teeth are provided on the underside of the chamber section of the barrel to lock securely into the receiver cuts prepared for them and provide a secure and positive mounting for the barrel.

The Slide and Breech Lock Mechanism. The slide incloses the barrel for its entire length. Its rear section serves as the breechblock, and it is suitably machined to travel back and forth in the receiver guides in a straight line. At its front end where it surrounds the barrel muzzle, it is machined to provide a seating for the forward end of the recoil spring.

In the breech section are housed the firing pin and its spring, the extractor and its spring, the safety, and a buffer pin each for the extractor and the safety.

When the pistol is assembled, a locking catch, spring controlled, which may be released by pressure on its projection in the forward end of the triggerguard, serves to keep the teeth on the underside of the barrel firmly locked to the receiver.

The firing pin and its concentrically mounted spring are of standard design; the spring serving to pull the firing pin back into the breechblock immediately after the firing pin (driven forward by the hammer) hits the primer of the cartridge in the chamber to discharge it. Thus as the action opens, the firing pin cannot be injured by the rearward pressure of the cartridge case being thrust back against the face of the breechblock, a thrust which is quite forceful in a blowback pistol.

Buffer pins inserted into the extractor spring activate the extractor under pressure of its spring both when snapping into the extracting groove in the cartridge case on forward movement of the breechblock, and in pivoting away from that groove as the ejector on rearward movement of the breechblock compels ejection through the port in the right side of the slide. The rear buffer pin retains the thumb safety in the slide in its applied position. These assemblies should not normally be dismounted. They are intended to be removed only for repair and by a competent gunsmith.

The Sights. The front sight in this arm is a part of the slide forging. A rib is matted on top of the slide for its full length. The rear sight is dovetailed into a cut in the rear section of the top of the breechblock slide.

The Receiver. The receiver forms the handle of the arm, guides the travel of the breechblock back and forth during recoil and houses the following parts: The rotating hammer, with its strut and mainspring assemblies and with pin to the sear lever; the trigger with its spring and pin; the trigger sear, the interruptor, the trigger catch with its spring and pin, the angle piece, sear lever, mainspring, ejector with spring, barrel holder with spring, grip plates and screws, magazine complete, and magazine catch and pin.

Safety. The safety in this weapon is a thumb lever mounted on the left hand side of the slide at the rear with a shaft passing inside the slide. On rotating the lever, the firing pin is pulled within the breechblock and its rear is elevated and locked so that the falling hammer cannot reach its head to fire a cartridge accidentally; and so that any straightline pin movement is impossible.

The Magazine Assembly. This consists of the standard steel box type magazine with sides cut away enough to permit counting the cartridges it contains. The magazine box has top lips which are folded over to permit insertion of cartridges from the forward end when they are thrust down on the follower and then slid in underneath the lips, and which are cut away at the rear enough to permit the head of the breechblock to hit the top cartridge and strip it into the firing chamber on forward movement of the slide. The follower or platform on which the cartridges rest, the magazine spring below the follower, and the bottom plate which serves as the lower compression point for the spring are the other components.

The magazine catch is a thumbpiece in the rear of the lower part of the grip which is pushed back to release the magazine for withdrawal from below. This catch operates under pressure from the mainspring which lies above it in the rear of the grip section of the receiver, and which thus provides two spring functions.

The Coordinated Action of the Parts

When the safety is off, and a loaded magazine is inserted in the grip, pulling back on the slide will cause the forward section of the slide around the muzzle to thrust back the recoil spring around the barrel against the abutment near the barrel chamber. This compression provides the motive power for forward motion of the breechblock-slide. The slide is machined in the rear breech section to permit it to thrust back and ride over the hammer. The hammer rotating on its pin thrusts its shaft (or strut) down, thereby compressing the mainspring mounted around it. The sear catches and holds the hammer at full cock. The magazine spring forces a cartridge up in line for feeding as the slide is pulled back far enough to clear the top of the magazine.

When the grip on the breechblock-slide is released, the recoil spring expands and thrusts forward on the head of the slide to drive it forward. The feed surface on the bottom of the breechblock face of the slide hits a cartridge in the top of the magazine and forces it into the firing chamber. The extractor through action of its spring transmitted through the buffer pin snaps the head of the extractor into the extracting groove in the cartridge case. The hammer is held back by a sear member called in this design the “trigger catch.”

If it is desired, any time the hammer is down in this weapon and the safety is off, the hammer may be pulled back by the thumb for cocking exactly as in a standard revolver. The advantage of this is that when the firing chamber is loaded, while a straight pull-through on the trigger will fire the arm, thumb cocking the hammer when there is time affords a lighter and smoother trigger pull, permitting better aiming for the first shot.

Preparation for firing with the safety applied. When the thumb safety is applied, the pistol is loaded for firing exactly in the same manner as when the safety is off. However, when the breech slide moves forward, the hammer cannot remain cocked. It will travel forward safely with the slide to closed position.

The hammer in moving forward cannot strike the firing pin. When the safety is turned, the cam surface on the safety shaft working against a cut in the firing pin suitably machined, pulls the firing pin further inside the breechblock away from the blow of the hammer, and raises its rear. Thus, when the safety is applied, a cylindrically shaped lock on the firing pin enters a hole in the breechblock which positively prevents the firing pin from moving in its longitudinal direction.

It is impossible to cock the hammer when the safety is on because the shaft of the safety locks the trigger catch (a sear-type member). As the slide is pulled back, it of course thrusts the hammer back and rotates it to the rear compressing the mainspring. However, as the safety is in the breechblock section of the slide, its shaft automatically depresses the trigger catch during forward motion, thereby preventing the hammer from staying at cock. This trigger catch is shaped as a lever.

The value of this system is that it is possible to load the firing chamber by pulling the breechblock-slide back over a loaded magazine with absolute safety. When it is not intended to use the arm immediately, the safety should be applied before the chamber is loaded. This device serves the further purpose, moreover, of permitting the hammer to be safely lowered on a loaded chamber. In the typical hammer-type automatic pistol, lowering the hammer on a loaded chamber can be dangerous, for if the hammer slips it may fire the cartridge. If the pistol is the enclosed hammer (called “hammerless”) type, it is impossible to lower the hammer on the firing chamber when loaded in most designs. (The Sauer Model 38 Pistol is an exception to this rule).

With this type of construction, when the chamber is loaded, the arm may be safely uncocked by merely pushing down on the thumb safety lever. This will (a) withdraw the firing pin within the breechblock away from the face of the hammer stroke, (b) lock it securely against longitudinal motion, and (c) then depress the trigger catch to let the hammer fall safely against the face of the breechblock slide.

The Action Which Takes Place During Firing

The gas pressure forcing back against the head of the cartridge case as the arm is fired, transmits the blow sharply to the face of the breechblock against which the case head rests. The breechblock-slide starts back in its guides in the receiver. The extractor carries the empty cartridge along with it until it hits the ejector and is thrown out the ejection opening in the right side of the slide.

This rearward motion of the slide compresses the recoil spring, cocks the hammer and compresses the mainspring as already outlined. As the slide moves back, the smooth face on its left rear bottom surface rides over and presses the interruptor down. (When the slide is closed and the arm ready for firing, the tip of the interruptor is nested in a notch in the underside of the slide on the left.) This pulls the trigger sear away from the appendage of the trigger catch. The trigger catch, thereby freed from trigger contact, prevents the firing of more than one shot. Pressure of the trigger catch spring forces the catch into the hammer holding it in cocked position.

The recoil spring carrying the slide forward after the completion of its rearward stroke, takes the top cartridge from the magazine and chambers it.

The extractor claw enters the groove of the cartridge case and the extractor protrudes about 1 mm outside the surface of the slide. This protrusion may be seen or felt. It is a positive indication that the firing chamber is loaded.

When pressure of the trigger finger is released momentarily the trigger spring moves the trigger forward and remakes contact between the interruptor, the trigger sear, and the trigger catch. Thus a pull on the trigger is transmitted to release the trigger catch, (or sear) from its grip in the hammer and permit the firing of the next cartridge.

This process is repeated automatically whenever the trigger is pulled. When the last cartridge has been fired, the magazine follower catches the breechblock and holds it fast. Thus the slide remains in rear position to indicate that the pistol is empty.

As the empty magazine is withdrawn, the ejector swivels into the place of the magazine platform to prevent forward motion of the breechblock-slide. Inserting a loaded magazine, then drawing the breechblock back far enough to free it from the ejector, will permit it to be released and to be drawn forward by the recoil spring to chamber a cartridge ready to resume firing instantly.

Closing and Releasing the Safety

Both these operations are performed manually. When the thumb of the right hand pushes the ribbed extension piece of the safety lever upwards and forward, a red spot is uncovered on the side to indicate that the safety is “off.”

When the ribbed extension piece covers this red spot, the safety is “on.” Note that the hammer cannot be kept cocked with the safety on as already described, and that the pistol cannot be disassembled until the safety is “off.”

Disassembling the Mauser HSc

Push the magazine catch and withdraw the magazine. Then pull the slide back to eject a cartridge, if any, in the firing chamber. Put the safety in “off” position. Cock the hammer. Then put the safety “on” again. Take the pistol in the left hand and with the thumb of the left hand press down the barrel catch or holder in the front of the triggerguard and at the same time with the right hand push the slide forward and remove it by lifting it off. Holding the slide in the left hand, with sights down and muzzle outwards, with the thumb and index finger of the right hand press the rear end of the barrel about 3 mm forward and then remove it together with the recoil spring by an upward lifting motion.

When the safety is “off” and the hammer is uncocked, this pistol cannot be disassembled. To attempt it will be to injure it. This is important to remember if you own one of these arms.

Reassembling the Mauser HSc

When reassembling this pistol, follow the dismounting procedure in reverse order. First, put the safety “on” and cock the hammer. Then insert the barrel and the recoil spring around it with a slanting forward motion into the slide. Hold the receiver in your left hand and put the slide (with the barrel and recoil spring in place in it) on the receiver guides from above with light pressure so that the front guide studs on the barrel fit into their corresponding recesses in the receiver. Retract the breech a trifle and then push forward to make sure it locks.