The following information on the flintlock pistol comes from The Book of the Pistol and Revolver by Hugh B. C. Pollard. The Book of the Pistol and Revolver is also available to purchase in print.

The type of lock known as the Flintlock was popular for more than two centuries, during which time it never underwent any substantial change in design. It was applied to every kind of firearm, from pocket pistols to cannon; and was the standard military system from the time of Charles II. to Waterloo.

The majority of collectable pistols belong to this period, and by far the greater number of them to the period of 1775-1830. To those collectors who have greater depth of purse, the earlier types are still accessible; but to the ordinary person the flintlock pistol period is the one that offers the greatest variety of interest for the smallest outlay.

There are two existing accounts of the origin of the flintlock pistol. One claims that it was invented by the Spanish or Portuguese irregulars, or “Miguelitos”—hence the French name, Lock a Miguelet; and the other tradition gives it Dutch origin, claiming that it was invented by the Dutch chicken thieves, “Snap-haans,” who could not afford wheel-locks, and found the match-lock, with its flaming match, unsuitable for their nocturnal trade. There is no proof of either of these legends being correct, and I have another theory to advance.

From 1542 the Portuguese had been trading with Japan. Existent at this time in Japan was a small form of flintlock, not applied to pistols or firearms at all, for these were unknown, but used as a portable tinder-box. These flintlock tinder-boxes are usually egg-shaped, and about the size of a small hen’s egg. They remind one of the modern “Easter egg,” and open into two sections, exposing the flintlock with a small receptacle for tinder. The trigger is usually an external stud. I advance the theory that these handy little devices would naturally appeal to the traveller of the period, and that some were brought back by traders or sailors to Portugal, where the principle was adapted to firearms. Its spread from the Peninsula under the name of Lock a Miguelet would naturally follow.

Many of these egg tinder-boxes are works of art, signed by well-known Japanese artists and metal workers. I have had no means of locating the earliest examples, but should any collector possess signed or dated specimens, I would be grateful for a note of the information sent to me in care of my publishers.

The earlier form of flintlock pistol was the type known as “Snaphaunce,” and it is intermediate between the real flintlock pistol and the wheel-lock. As it was only made during a short period, it is the rarest of all forms of pistol, and the value of specimens is rapidly increasing, few being left outside museums or large private collections.

The Wallace Collection and the Birmingham Art Gallery have beautiful collections of snaphaunces, mainly of Italian workmanship; and it is seldom that snaphaunces by European makers other than Italians are met with, though they were made in England as early as 1585.

Their difference from the flintlock pistol is unmistakable, for they retain the sliding pan cover of the wheel-lock, and the steel or frizzen is not combined with the cover, as it is in the flintlock, but independent.

The internal mechanism of the lock is similar to that of the wheel-lock, for the same system is employed to uncover the pan. The snaphaunce principle is sometimes met with in Tartar and Caucasian pistols of later date, but the finest specimens are the Italian weapons by Lazzaro Comminazo, and Geo. Maria Aquisti.

The standard flintlock came in about 1630, and was popular for some two hundred years. The principle of the flintlock is simplicity itself. A flake of flint held in the jaws of a pivoted lever, now called the “hammer” but then called the “cock” is driven by a spring against an upright extension of the cover of the flash-pan, called the “frizzen.” This when struck by the flint is thrown back, uncovering the priming powder, upon which the sparks resultant from the collision of flint and cover fall. The cumbrous winding up or “spanning” of the wheel-lock was thus done away with, together with all other businesses of uncovering the flash-pan, and setting down the serpentin.

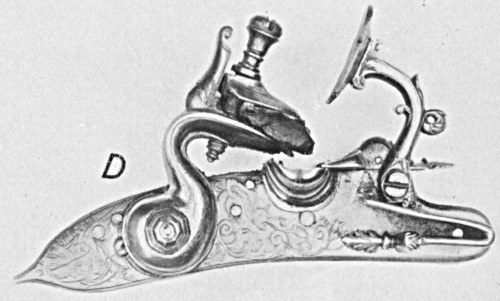

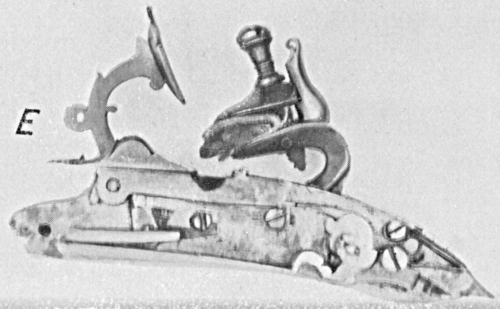

There are two other forms of flintlock that deserve notice, and these are the types used on Spanish and Arab firearms, in which the whole of the lock mechanism is external, and of two types. In one the mainspring pushes up, in the other down. The trigger action of both these types is distinctive, and evidently adapted from the wheel-lock.

In the wheel-lock the rotating disc is held cocked by a pin that passes into a hole in the disc from inside the lock plate. In the Spanish lock this pin is retained, and serves to support an extension of the hammer. Pressing the trigger draws the pin back by means of a bell-crank lever, and the hammer is brought down by the pressure of the spring. All Spanish and Oriental locks of this type have serrated steel frizzens dovetailed into the soft iron of the pan cover.

European weapons have almost invariably plain steel pan covers. These serrations are distinctively Oriental. The Spanish have always been ultra-conservative, and the Moorish tradition still continues. In modern Spain one can find cheap breech-loading fowling-pieces with the same pin release to the hammer as was used on the earliest firearms.

Flintlock pistols fall into three main groups, according to the purpose for which they were designed, but the line of demarcation between the groups is frequently crossed by weapons designed to suit general utility purposes, hybrids between the two main types.

The great divisions of the period are: (1) Horse or holster pistols, which embraces all large pistols; military and naval models; (2) duelling pistols; and (3) pocket pistols. Into one or other of these categories nearly all muzzle-loading pistols can be placed.

During the latter part of the seventeenth century, in Charles II.’s reign, it was ordered that the standard military pistol should not be less than sixteen inches in length over all. By 1700 the pistol began to grow less cumbersome, and the average size was about twelve inches for officers’ weapons, though the rank and file still retained the cumbrous and crude earlier type. The notable weapon of the Queen Anne period is the type known as the “cannon barrel.” This variety of pistol is distinguished by the shape of the barrel, which is outwardly turned to resemble an old-fashioned cannon. The barrel is screwed to a breech-block, which contains a tapering powder chamber of less diameter than the bore of the piece, and the whole is designed for loading from the breech with a well-fitting ball, thus obviating all danger of the bullet rolling out, the barrel being more or less chambered or relieved at the rear to accommodate it.

The cannon barrel pistol was made in a variety of sizes and in several types, but the earlier specimens are usually from ten to twelve inches over all, about twenty-two bore, and have a distinctive lock. The action is fitted in a box behind the breech of the barrel; the hammer is at the side, and the frizzen spring lies underneath the pan, curving round to a point midway between the pan and the hammer. A specimen in the author’s possession carries on its silver mounts the hall mark for 1705.

The second type of cannon barrel is the later model, probably about 1720, and has an ordinary side lock attached to the wooden butt, but not part of the barrel. The wood fore end terminates abruptly as soon as it is clear of the lock. The lock is held to the butt by two screws passing through a metal strap on the opposite side.

Models of this description are usually found in pocket sizes, and were made for concealment in the large “salt box” pockets of the costumes of the period.

The third and most common model of cannon barrel has an inside box lock extension to the breech, but the hammer is not at the side, but vertical, and in the line of sight. The frizzen and flash-pan are on the top of the barrel, and it is similar to most of the flintlock pocket pistols in having no possible line of sight along the barrel. The dates of this type may be anywhere between 1740 and 1800.

The rare Scotch or Highland pistols were often of this cannon barrel type, and some were equipped with a ring butt to serve as a key for unscrewing the barrel of the companion pistol. These Scotch pistols were made during the seventeenth and eighteenth century to match Highland costume, and were made with metal stocks, either plain or engraved, in steel, or occasionally in silver. The locks may be either outside hammer or enclosed, and in some the Spanish type of lock is preserved. The triggers are of the knob type, similar to the Russian Cossack pistols. At present they command an exorbitant price, and modern imitations or “conversions” are not unknown.

All types of cannon barrel pistols were highly ornamented and inlaid, and most butts terminate in a silver or brass mask. They were essentially gentlemen’s weapons and expensive to make, but contemporary with them ran the standard military pistols and pairs of horse pistols of the period.

The early flintlock horse pistols had substantial metal knob butts, and the stock was straighter than the conventional “pistol grip.” The knob butt served a double object in securing balance and serving as a club or mace for use at close quarters.

The style of butt is termed by some “fishtail,” as the knob bulges out just as a fish’s tail splays outward. From the metal knob run up two slender curved wings of metal inlaid into the wood of the stock, these serving to strengthen it at its weakest part.

The origin of this type is probably Italian, but all good European arms of the period, other than cannon barrels, used this type of butt.

The barrels were round, made of thin steel, and thickening towards the breech. In some cases the shape turns to octagon for the breech end, but completely octagon barrels are a later type.

The muzzles were slightly “swamped” or belled outward. This must not be confused with bell-mouthed pieces, but means that if a straightedge is laid along the barrel from breech to muzzle the line of the barrel shows us a graceful curve. This principle gave better balance owing to the weight of metal at the muzzle, and was easy to sight. It was only employed on good class weapons.

The distinguishing marks of the early eighteenth-century horse pistols are thin barrels, knob butts, and bent lock plates—that is to say, the lower edge of the lock plate is not straight, but dips towards the stock. The section of the hammer is oval, a hammered forging, not as if the hammer had been cut out of a flat piece of steel, and there are seldom any sights.

As the art of manufacture advanced, barrels got heavier and more accurately welded. Grace of design and a wealth of inlay and ornament distinguished the Italian and French weapons, and at the middle of the eighteenth century a gentleman’s pair of pistols were objects of art. Sights, with the exception of a bead for a foresight, were unusual; but the graceful design of the stocks, the balance and the “lay” of the pistols, ensured an automatic accuracy, merely pointing them at an object bringing them on with sufficient accuracy to hit your man instinctively at distances up to twenty paces.

The pistols of the period were made in styles of finish suitable to the social order of the age: exquisite works of art for the nobility, plain but graceful and reliable weapons for the gentry, and coarse, cumbrous, but efficient equipment for the middle and lower classes.

Pistols were made as a rule in pairs, but cases did not come in until the days of duelling pistols, as most weapons were sold with leather holsters for attachment to the saddle.

The period of 1750 to 1775 develops the pistol from the ornate cannon barrel and decorated horse pistol toward a weapon of greater weight and solidity, capable of vastly greater accuracy. The tendency is best described as abandoning shot-gun lines of construction for the heavier and more deadly rifle.

After 1780 duelling with small swords went out of favour, and affairs of honour were settled with the pistol rather than the blade. Stimulated by this, makers turned their attention to the production of a heavy, accurate pistol, warranted to hit a halfpenny at twenty paces, and pistol design was so soon influenced by the development of this superior weapon that all other types of pistol speedily followed the prevailing mode.

The luxurious mountings, chiselling, and inlay gave place to a plain serviceable weapon of first-class workmanship and magnificent mechanical and ballistic efficiency. The graceful round barrel of light metal yielded to the heavier octagonal form. Bright silver fittings were replaced by bronzed or blued steel that would not glitter in the sun and attract an adversary’s aim, and locks of sure and certain action were of greater value than graceful ornament.

The English makers won a reputation surpassed by none for the plain excellence of workmanship, and solid reliable design suited their natural expression as makers of weapons rather than makers of objects of art, and it was in their hands that the British duelling pistol reached its apogee as the most accurate and reliable flintlock pistol ever produced. They were plain, but exquisite in craftsmanship, shooting power, and balance—a triumph of the gunsmith’s art.

The names of Joseph Manton, Mortimer, Durs Egg, Wogdon, Nock, Blanch, and Rigby, were known and honoured all the world over wherever pistols were used or needed.

The English duelling pistol in its first period retained some of the graceful lines of its lighter forerunners, but later examples sacrifice grace to sterner needs.

The typical duelling pistol is of half-inch bore or less, has a nine or ten-inch octagon barrel of smooth bore, and a plain, light trigger pull. The stocks are usually of walnut, and free of ornament. The barrel is secured to the stock by flat holding-down bolts, and the lock strap—the piece of ornamental metal on the opposite side to the lock—is done away with, though the lock is held to the stock by two screws termed “side nails.” The ramrod is carried under the barrel, and is horn, not metal, tipped, and the wood of the stock extends to the muzzle.

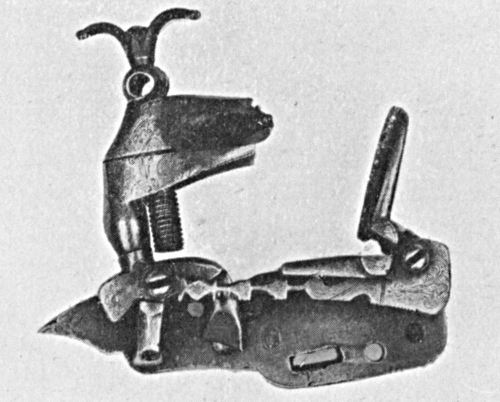

The same type of pistol endured till superseded or converted to the percussion-system, but certain small changes came in. One of these was the introduction of the “detent,” a moving intercepting lever in the lock, whose function was to prevent a hammer slipping while being cocked, and firing the charge. This it accomplished by guiding the scear into the half-cock notch upon the tumbler, and so arresting the blow of the hammer before it struck the frizzen. Next in importance came an improvement to the frizzen action.

The blow of the hammer has to force the frizzen back round a pivot, and against a spring on the outside of the lock plate. This spring has two functions to perform. One is to give the frizzen sufficient resistance to strike sparks from the flint in the hammer jaws; the other to keep the pan cover section of the frizzen down tight on the pan to prevent accidental loss or damping of the priming powder. By about 1790 it was the custom to place a small wheel built in with the frizzen spring at the point of friction between frizzen stem and spring. This wheel acted as a roller, and eliminated the slow friction, with the result that the pan opened much more quickly, and the priming received many more sparks, ensuring a quicker and more certain ignition.

Another detail of interest is the extension of the trigger-guard toward the barrel. This is usually more or less decorated, and of fancy design; the earlier weapons up to, say, 1790, have an acorn pattern, possibly of Jacobite origin, Towards 1800 and thence onward this develops into an unmistakable pineapple, possibly a design started by the West India trade.

Military and naval weapons were distinguished by the crudeness and simplicity of their manufacture, the later models having a metal ramrod attached by a ringed stirrup to the stock to prevent its loss while reloading. They, as well as many other types of pistol, are often provided with long belt hangers at the side for carrying in an accessible position while in action. With the exception of a few very late models of military weapons, it is unusual to find any flintlock pistol provided with a swivel ring in the butt, as is customary with modern military arms. In early military models, the wood forend reaches almost to the muzzle and is secured by pins, but in later types it shows the influence of the duelling pistol design and reaches only half-way, and is bound to the barrel by metal rings.

Previous to 1780 the usual hammer was of the swan-neck type, except in miniature pistols and some military models. The thin neck of the hammer was one of the weakest points in the weapon, and had of necessity to be made of fine quality steel. It was superseded by the double-necked or loop-hammer, in which the screw that tightens the jaws of the cock upon the flint passes into a double loop, giving it additional strength to resist the blow upon the frizzen.

In first-class duelling pistols the old swan-neck was long retained, but in early nineteenth-century flintlock pistols the loop-hammer, in a neater and more compact form, is more usual than the other.

The difference between duelling and horse pistols is often slight, many arms being made for use in either capacity, but bores of over twenty-eight—that is, half an inch—were seldom used for duelling purposes. Against this must be set the fact that pairs of pistols of duelling pattern were made for officers in seventeen bore, to take the Government ammunition of the period, and it is doubtful if these were not in frequent use for military duels of the period.

Brass or gun-metal barrels were popular for military and horse pistols, but never for duelling, and the last type of military officer’s pistol abandoned the octagon type of barrel for a very heavy round barrel with a flat along the top for sighting, a type which was popular for house and carriage pistols.

Pocket pistols followed the trend of improvements in the larger pieces, and are usually of top hammer action, with enclosed lock, folding triggers, unscrewable barrels for loading at the breech, and a sliding safety bolt that locks the cover of the flash-pan to prevent the accidental escape of the priming while in the pocket. The same model, but with ordinary trigger and trigger-guard, was equally popular.

The pocket pistol was always the subject of experiments in the direction of greater rapidity of fire, and to it were applied a variety of queer attempts at double and repeating mechanisms.

The only one of these that seems to have had any vogue was the tap mechanism, in which barrels were arranged one above the other.

The top barrel was fired in the ordinary way; then the pan was closed again, the hammer recocked, and the tap turned. This tap served as a false bottom to the pan, and being turned through 180 degrees, exposed a second charge of priming lying in a recess in the tap itself, and communicating with the lower barrel. The pistol was fired a second time, thus discharging the lower barrel.

There is a piece by Knubley of London, in the author’s possession, which has this principle, but four brass barrels arranged in under and over pairs. The right-hand pair are kept isolated from the left by a sliding-pan cover, and the functioning of the weapon is—Left top barrel fires; turn the tap, left lower barrel fires; pull back slide, right top barrel fires; turn tap back again, lower right barrel fires. The frizzen has to be closed, and the hammer recocked for each shot. A patent for this type of weapon was taken out by Simmonds of Birmingham, a notable maker of brass barrelled pistols in 1770.

A favourite attachment to pocket pistols is a spring bayonet lying on top of or a1ong the barrel. When a catch is released, this springs out and locks in position, allowing the weapon to be used as a dagger. This device is the patent of John Waters, of Birmingham, in 1781.

Pocket pistols of a cheap type were made by wholesale firms and sold to gun shops all over the country. They are seldom of much value, unless of first quality and well decorated, and are not often found in cases.

The exact dating of pistols is a very complicated subject, owing to the practice of bringing the family weapons up to date. The old pistols were so good that it was frequently thought desirable to bring them up to date with a new lock, rather than abandon the beautiful workmanship of stock and barrel as obsolete. I have by me as I write an Irish pistol with a stock of the period of 1720, a long barrel of the same period proved and marked “Dublin,” and a lock of some seventy years later by Lord and Hutchinson, engraved to match the original style of the piece. Conversions of flintlock pistols to percussion are common, particularly with expensive silver-mounted pieces, and such conversions detract considerably from the value of the piece to a collector.

Sometimes an idea of the date of manufacture can be gained from the hall-marks on the silver mounts or masks upon the butts, but the author has seen specimens of late percussion model pistols with silver mountings of a century before, so little reliance can be placed upon such dating.

Proof-marks are of value, but many pieces of early manufacture lack these, and they give no indication of the date of manufacture, and it is only by experience and a knowledge of the difference of type and design, mountings, and manufacture, that one can approximately place the date of any definite specimen.

To aid such research I have compiled a list of makers with the periods at which they were in business. It is incomplete, but anyway a beginning. Owing to the fact that many retailers styled themselves “gunsmiths” and makers, it is not easy to tell if some of them actually made as well as sold pistols, but between the proof-marks the maker’s initials or trade-mark often occurs, and these sometimes fail to tally with the name of the barrel.

Pistols are often found with different names on the lock and on the barrel. This is due to later alterations, and is not necessarily a defect.

Pistols with left-handed locks are uncommon, and any unusual variety of flintlock pistol of European manufacture, be it multi-barrelled or unusual in design or finish, is, as a rule, well worth collecting, but to picture or describe unusual pieces is outside the scope of this little work. Single specimens of pistols that go in pairs, like duelling pistols, are not of so much value or interest as complete pairs with case; but a good single specimen is always better than a bad pair.

When pairs are in cases it is desirable to have all the accessories complete and correct. In nine cases out of ten the bullet mould found in the case is not the correct size; and often the powder-flask, is of a later date.

Now, for collectors’ purposes, it should be seen to that all the fittings in the case, and the case itself, suit and are adaptable to the weapons in question—a perfect outfit complete in all details being the only correct way of keeping pieces.

I always make a point of purchasing any old bullet-moulds, powder-flasks, or fitments, that I come across in order to replace missing or incorrect pieces.

A complete case should contain a bullet-mould, a powder-flask, a cleaning rod, patches, bullets, turnscrew, spare flints, and pewter oil bottle.

In very complete sets a cutter for cutting out the patches, and a small priming flask, or miniature of the big flask, are also included. Spare flints can be got from the flint knappers at Brandon, or from most good curio shops where arms are sold.

Powder-flasks of the flintlock period are always pear-shaped, made of thin copper, and with a spring cut off. To load, a charge was measured out by placing the finger on top of the spout, holding the flask upside down, and pressing the spring for an instant. The flask was then righted, the finger removed, and the charge poured down the barrel.

A bullet free from excrescences where the stem from the mould had been cut off was next selected, placed on a circular waxed cotton patch on top of the muzzle and forced down upon the charge with the ramrod.

The pan was next opened and a small charge of fine grained priming powder poured into the recess, the pan closed and the pistol turned lock uppermost, and tapped to allow the powder to run into the touch-hole.

It was then in a condition to fire.

With cases of percussion pistols, a variety of other accessories are also found. These are nipple keys, prickers (these are often combined with the turnscrew), and, in the case of muzzle-loading rifled pistols, a mallet and rammer to drive the bullet down. Late Continental duelling pistol sets have a variety of other small fittings as well.

The flask of the percussion period is not pear-shaped, but oval, and flat-bottomed, and is usually provided with two internal chambers to take a few bullets, and some caps as well. Many of the best of these were made by Sykes, and, though comparatively modern, are already getting scarce.

Bullet-moulds are provided with a small pair of cutter blades at the back of the mould. These are for the purpose of cutting off the projecting spigot of lead after casting.

The ends of the handles are often shaped as turnscrews, barrel wrenches, or ramrods, and most moulds have the size of the bullet they cast stamped on the handle near the cutter.

The flintlock pistol period is the richest for the collector, but it is only worth while collecting good stuff. The antique shops are filled with highly ornamented rubbish: genuine flintlock pistols, it is true, and highly decorated, but nine-tenths of it is Turkish and Greek trade “antiques.” Flintlocks of the most valueless description were exported for the Eastern market, where they received crude decorative treatment with brass wire, base silver, and pewter, inlays, and ornament; they then return to Europe as “genuine antiques,” and sell for about thirty shillings apiece. Few of these have ever been fired; none of them are meant to be, but the collector should beware of all Turkish, Albanian, and similar pieces; in nine cases out of ten they are pure fakes, built out of scrap for the antique market.

Good Oriental pieces are scarce, and a great deal of knowledge is required to distinguish between the good and the bad. The collector will be well advised to neglect this branch until such time as he has acquired a sound knowledge of European pieces.