The following information on the values of electric motors comes from Five Acres and Independence by M. G. Kains. Five Acres and Independence is also available to purchase in print.

Value of Electric Motors

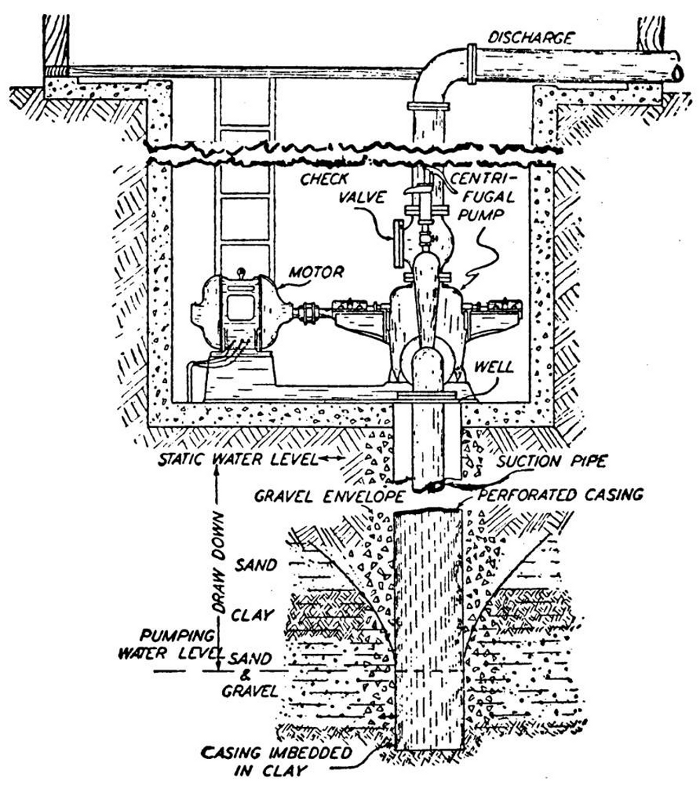

The electric motor is the most dependable and economical power for operating farm water pumps, provided the cost of current is not excessive. Pumps are of two classes, shallow and deep-well. The first are designed to lift water from wells or cisterns the bottoms of which are not more than 22′ below the level of the pumps themselves; the second, where the vertical lift from the water to the pump is greater.

Shallow-well pumps may be placed above or near the wells or cisterns from which they draw water; e.g., a basement where they are protected from freezing. Deep-well pumps must be placed above the well, though the pressure tank, if any, may be located elsewhere. A pump jack, if used, with either a shallow- or a deep-well pump, must be placed over the well or cistern when used with a deep-well pump.

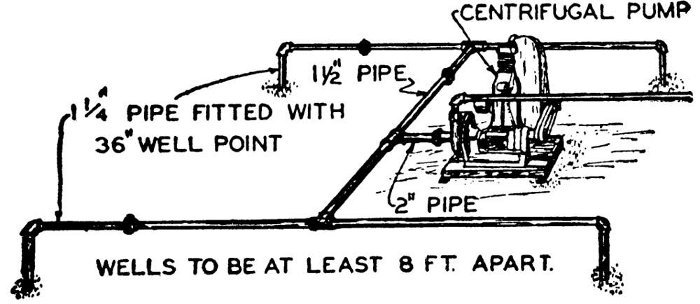

When considerable water must be pumped the arrangement shown here will often be found less costly than to sink one tube of total, equal capacity because, when soil conditions are equal, it is easier to drive the smaller pipes than a large one and the flow is likely to be surer. Shallow wells, 15′ to 20′ deep, may be connected together and connected with one pump.

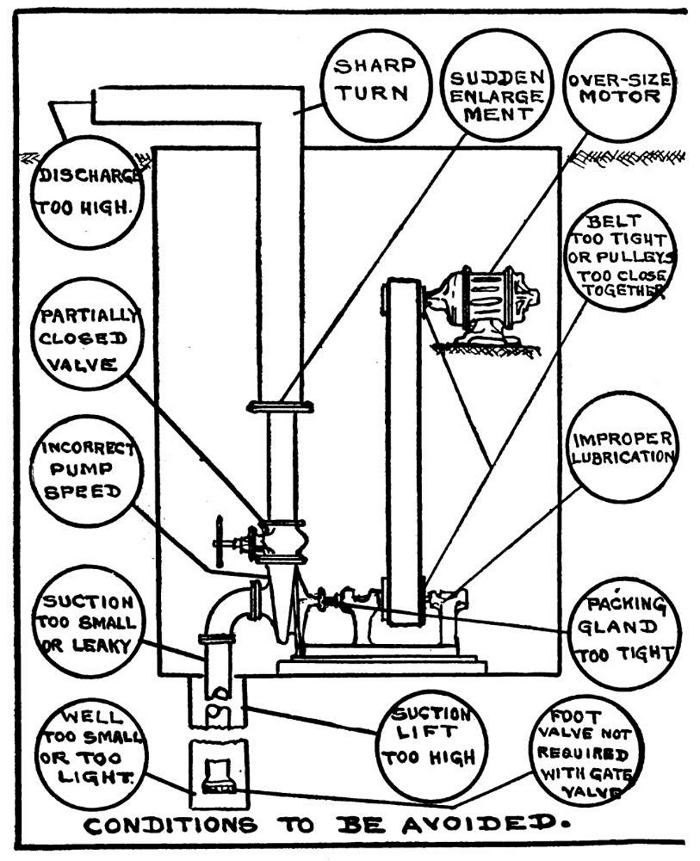

Changes from engine to electric motor to operate pumps rarely involve much change of equipment. In most cases the drive pulley must be replaced by a larger one to secure pump speed. Where automatic operation of the motor is desired, a switch to control the motor must be installed. When belt drives are used, some style of belt tightener will be needed.

Always the wiring for motor installation should be done by a competent electrician and fuse plugs of proper capacity used to prevent damage to motors.

The amount of water pumped by electric current or a gallon of gasoline per kilowatt-hour depends upon various factors such as size and class of pump, depth of well, and pressure against which the water is pumped.

In tests of 5 pumps at the Indiana experiment station (reported in Circular 184) the average consumption with a 15′ lift at 30 pounds gage pressure was 1.25 kilowatt-hours per 1,000 gallons of water pumped. Similar results, secured on 5 farm-installed, shallow-well pumps where the water pumped was measured by meters, showed a consumption of 1.44 kilowatt-hours per 1,000 gallons of water pumped, with pressures varying from 20 to 40 pounds. Energy required for pumping with deep-well pumps is greater than that with shallow-well pumps and increases with the increase in lift of the water.

The average of 8 field survey records taken on shallow-well pumps driven by gasoline engines showed a consumption of 1.05 gallons of gasoline per 1,000 gallons of water pumped against no pressure, and similar records taken on 5 shallow-well pumps driven by electric motors showed a use of 1.56 kilowatt-hours per 1,000 gallons against pressures of 20 to 40 pounds.

With gasoline costing 12c a gallon and electric energy costing 5c a kilowatt-hour, the cost of pumping 1,000 gallons of water under the above conditions were $0.78 for electric power and $0.126 for gasoline power. The results of the tests reported would indicate that under identical pumping conditions (both pumping against the same pressure) a greater difference in cost of power would result.