The following information on revolver and pistol repairs comes from Section 26 of Shooting by J. Henry FitzGerald. Shooting is also available to purchase in print.

For many years I have followed the adventures of the amateur gunsmith and have observed the results of his labors. In some cases I have been agreeably surprised at the results and in other cases I have also been surprised and astonished at the number of things Colonel Colt forgot to do when he built his revolver and pistol. If sears, hammers, and other more or less necessary parts of the revolver and automatics had the growing qualities of tomatoes I believe a profitable crop could be gathered around the firing line at Camp Perry and other ranges I have visited. Therefore I am just a little in favor of the factory-corrected shooting irons.

One little improvement which was brought to my attention some years ago at the big shoot was a new method of fixing the trigger pull. Several .45 automatics were handed to me for adjustment and I found one side of the hammer notch gone by way of the file. I inquired why this was done and the men informed me that the pistol had at first a seven-pound pull and by taking off half the notch they expected to get a three and one-half pound pull. The only trouble was that the thing doesn’t work that way.

Improvement number two—the persons or person who invented the scheme of splitting the locking lugs in the slide with a chisel; well, that also passed away.

I believe the greatest enemy of a gun is an oilstone in the hands of a person who does not know how to use it properly. Then the ordinary oilstone is not as smooth as a number six Swiss file about half worn out neither can you get to the corners as well with a stone as with a file. Though you may stone the hammer notch and sear ever so smooth let one part slide over the other and you have a beautiful creep.

It must be remembered that the object of the notch is to create a trigger pull of a certain weight, but whatever the weight required, be it two and one-half, four, or six pounds, it must pull clean. That is, the weight required to start the trigger or sear out of the hammer notch must pull it clear over the top of the notch. In the .45 automatic the mistake is often made in dry shooting before the sear is seated by actual shooting after the pull is adjusted.

In a revolver a pull may be lightened by using a lighter spring. If a lighter spring is not available the original spring may be ground or filed. Care must be taken, however, to grind or file the leaves of the spring lengthwise and to file nearly the entire length of the top and bottom leaf. The points of hammer and trigger, which constitute a smooth, clean trigger pull, are as delicate as some points in a watch. A man must be an expert with a file to change these points and leave both surfaces in position to bear evenly at all points. Two or three thousandths in the wrong direction will ruin a very fine pull.

If a revolver is to be taken apart the first requirement is a screw-driver that fits the screws, placing the thumb of the hand holding the revolver in such a position as to guide the screw-driver into the screw slot without slipping, otherwise the head of the screw and the adjoining frame will become scratched and defaced.

Sometimes a burr on the firing pin hole in the revolver will bear against the head of the shells and in this way block the turning of the cylinder; this may be removed with a small file. Here is one of the first places to look if the action does not work smoothly. Another trouble which will cause a jammed action is a bullet jumping forward in the cartridge next to the one being fired. Care should be taken when a jam occurs not to use excessive force as this may damage the action. Side plate screws should be examined when the arm is cleaned as they sometimes work loose and if this happens the mechanism may slide out of place, causing a jam.

I have always claimed that it takes between five hundred and one thousand shots to break in a revolver before it will do its best work and the owner accustoms himself to hang, trigger pull and sights, but this does not mean that good work cannot be done before this breaking-in process. I have seen a great many of the profession appear on the firing line after a trip to Commercial Row and win the price of the arm the first day; however, I still claim they will make better scores with the arm after the above-named number of shots.

Remember, dropping any hand gun does not improve the shooting. Neither does it improve the shooting to take the revolver in one hand and when the cylinder is open throw or snap it back into place. If you wish to save scratches and other cylinder trouble hold the revolver by the handle or grip, grasp the cylinder with the thumb and forefinger of the other hand, thumb on left side of frame, forefinger on right side of frame in depression between chambers, and close with depression halfway between top and bottom strap and close until locked by latch.

Many things can happen to a revolver and so it can to any other piece of mechanism whether it costs twenty-five dollars or twenty-five thousand dollars. I do claim that many things that happen are sometimes the fault of the shooter. For instance, taking the arm apart when it is working properly, polishing and stoning parts and working points, putting undue strain on parts by holding cylinder when cocking the arm. I have noticed thousands of shooters testing a revolver for a creep by using both hands and placing the left thumb behind the trigger when pulling with the right. The proper way to test for a creep is to hold the arm out in a natural shooting position and then try to find the creep.

Shooters spend many hours designing new grips for their pets but if this time was spent in shooting perhaps another champion might be with us. Many times a shooter can change his sights if he is careful and works slowly, and thus improve his scores, but care must be taken that he does not change them in a way that will bar his arm in certain matches. He should also be careful not to damage the muzzle or change it in any way.

If an immovable front sight is to be moved to right or left it should be done by turning the barrel in the frame. This can be done by fitting two blocks, one on each side of the barrel, either of wood or soft brass cut out to the exact taper of the barrel, the blocks not quite meeting (about 1/8″ apart) when the barrel and block are placed in vise, first removing the cylinder and crane from the revolver. Paper should be used between blocks and barrel to protect the bluing. Use a piece of hard wood one and one-quarter inches square and one foot long placed through cylinder space; hit a series of light blows on the end of the stick until the barrel is screwed in or out to the required distance. The barrel must not be moved back and forth many times or a loose barrel will be the result.

A jam is sometimes caused in an automatic pistol by the extractor not grasping the head of the shell firmly. To test for a possible jam at this point, remove hammer from the pistol to avoid accidents; take out magazine and place cartridge in the chamber; draw slide back slowly and just before the rim of the shell touches the ejector at left side allow the slide to go slowly forward and note whether the cartridge is held in place by the extractor. If the extractor has the proper tension or grip on the rim of the cartridge it will return to the barrel chamber as slide goes forward; if tension is insufficient the cartridge will drop at front end and sometimes drop down through the magazine cut or space. If this should happen, take out the extractor by removing firing pin stop and bending front end three-quarters of an inch from point slightly inward; replace the extractor and again try the chamber test. When it has the proper tension the cartridge will return to former position in the chamber. Some of the jams in the .45 automatic come from a wartime magazine because the sides or lips are spread apart and rear top corners are split. There is no cure for this except a new magazine of commercial quality.

We do not have the troubles that I will now mention with the new commercial arms, but with the war products and those through long use or neglect that have had new parts replaced for the old and that were not properly fitted. At this time may be mentioned that from these improperly fitted extractors comes the annoying shell that will come back when extracted and strike the shooter in the face or some part of his body. This is caused by the bottom corner of the extractor hook not being rounded or filed away to allow the shell, as it is pushed over by the ejector, to leave the recoil plate at an angle that will carry it through the porthole in slide at any angle that will cause the shell to go to the right of the person holding the pistol. A properly filed extractor hook will eliminate this trouble. I encounter every year at the camps automatic pistols that have slides from one pistol, a receiver from another, as well as other parts from different pistols, but if these are fitted properly they will work perfectly.

Misfires with some of the cartridges used at the big shoot are unavoidable as the primers are very hard and even with the heaviest of springs and perfect firing pins this will occur. If, through defective ammunition, a bullet should stop in the barrel be very careful in driving it out; protect the muzzle from contact with the rod, with cloth, paper, or other substance when driving the bullet out, and clean the barrel thoroughly, for particles of steel, brass, or grit may become detached from the rod and the next bullet may scratch the barrel.

The front sights now furnished on the commercial pistols will not jump out. I have cut over hundreds of the front-sight slots in the older pistols to take the new sight and they can hardly be pulled out with a vise. If one-eighth or one-tenth inch front sight is used, this new type of sight with heavy square base is the only one the shooter can depend upon.

As issued for government use the .45 automatic has a long hammer spur and it is not an uncommon sight at the different ranges to see the shooters with a piece of adhesive tape between thumb and first finger. This spur may be partly ground off on an emery wheel if it interferes with good scores by striking the flesh between thumb and finger.

The greatest improvement which can be made on a .45 automatic pistol is the fitting of a new match barrel. When fitting a barrel to some of the old automatics place the barrel in arm; draw slide rearward until it locks open; then insert little finger through port, draw it upward on runway to assure yourself that bottom edge of barrel does not extend out over the runway, for if it does it will cause a jam. Remove the protruding edge with a file, taking care not to change angle of runway in barrel and leave a runway smooth for bullet to slide over.

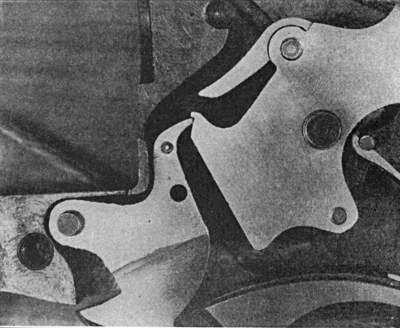

Such work as fitting new hands and bolts should be done by the factory or a first-class repairman, because if parts are not correctly fitted the revolver is out of time. Drawing the hammer rearward will show whether the bolt is falling correctly or not. It should fall near middle of bolt runway in cylinder, then slide forward to bolt cut in cylinder. If it falls too early it will fall before it reaches bolt-cut runway and mar the fine finish of the cylinder. If it falls too late it may cause a throw-by, in factory terms, or fall beyond the bolt cut. This timing is corrected by shape and size of bolt at the rearward end as it drops from spur on lever. Sometimes after fitting a new bolt the hammer cannot be cocked because the bolt will not lift out of bolt cut, which may be corrected by changing curve of lever.

While I could go on and on through the different repairs that may be required with revolvers and automatic pistols I will again state that the factory or a good repairman in your own town is by far the safest for your favorite arm. Tools less experience mean nothing, and experience less tools means the same thing.

Perhaps if I had not had handed to me thousands of fine revolvers that had been nearly ruined by homemade adjustments I would get a thrill out of this section and proceed with the entire bag of tricks necessary to place your revolver in new condition. I do not mean to discourage those who are capable of repairing their own arms, but to discourage those who are not, before they get into serious trouble.

Mention has been made of emergency repairs which I have made at different ranges. The repairs which I have made at different ranges were not emergency repairs but correct repairs, if proper parts and tools were available. If not, the owner was notified of the fact and advised to return arm to factory for proper adjustment.