The following information comes from The Book of the Pistol and Revolver by Hugh B. C. Pollard. The Book of the Pistol and Revolver is also available to purchase in print.

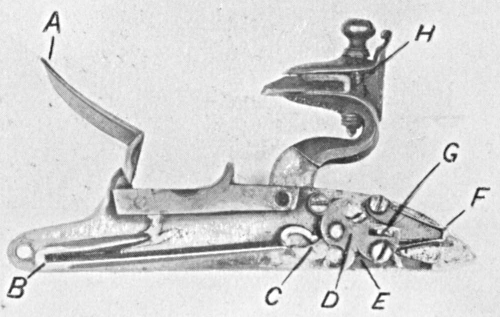

Names of the Principal Parts of a Flintlock Pistol

Bolts—Pieces of steel that push through the barrel loops to fasten the barrel into the stock.

Bridle—The curved piece of steel which holds the scear and tumbler in position against the lock plate.

Cap—Tip of stock or covering for worm of ramrod.

Chain or Swivel—The little catch piece joining the neck of the tumbler and the mainspring. This is probably so called from the old wheel-lock, when this member often was an actual link or two of chain.

Chamber—The centre or principal tube in the breech screw. The antechamber is the smaller tube leading from touchhole to chamber.

Cockscrew—The screw that tightens the jaws to hold the flint.

Escutcheons—Pieces of metal or silver to prevent the bolts wearing the stock; also applied to the shield on which crest or monogram was engraved.

Facing or Frizen—Part of pan cover, or frizzen, which strikes fire from the flint.

False Breeching—The part where the breech of the barrel hooks in before the barrel can be fastened to the stock.

False Breeching Screw—The screw which secures this to the trigger plate.

Feather Spring—The frizzen, or pan-cover spring.

Fence—The curved guard of the pan that arrests the fall of the hammer.

Frizzen Brindle—The part that the frizzen extension works in.

Guard—The bow which defends the triggers.

Jaws—The lips of the cock or hammer that hold the flint.

Loops—The eyes that hold the pins or bolts that secure barrel to stock.

Mainspring—The spring that works the tumbler and cock on hammer.

Nipple—The projection of the touch-hole on which a cap is placed.

Pipes—The bands on the stock to receive the ramrod.

Scear—The part which engages with the notches on the tumbler and holds the hammer at half full cock.

Scear Spring—The spring that presses the scear into position.

Scroll Trigger or Spur Trigger—An extra extension of the trigger-guard to steady the hand.

Side Nail—The screw that holds the lock in position.

Tail—The arch, neck, or extension of the frizzen.

Trigger Springs—Small springs invented by Joseph Manton that keep the trigger always pressed against the scear.

Tumbler—The moveable centrepiece of the lock that moves with and directs the hammer or cock.

Tumbler Screw—The little screw that fastens the hammer to the tumbler pin.

Worm—Screw end on a ramrod for drawing wadding.

Note.—On the flint-lock weapons the hammer, as we understand it to-day—that is to say, the falling member that held the flint—was termed the “cock”; the frizzen or steel or flash-pan cover was termed the “hammer.” Later, when the percussion system came in, the cock was called the “striker,” and gradually has come to be known as the “hammer.”

Throughout this book I have called it the “hammer,” as this name is less misleading to modern minds. When reading old books, it must be remembered that the term applies to the “flash-pan cover.”

Frizzens and springs were easily worn out and often replaced, and nearly every gunmaker had his own idea about how a frizzen should be made and fitted so as to give good fire and waterproof protection to the priming. The test of a good frizzen was that it should “shut down dull and fly back smart.” Frizzens could be “new steeled,” that is to say, the steel plate welded on to the front of the frizzen renewed, but in most cases it was simpler to put in a new “hammer,” and gunmakers always encouraged this process.

Colonel Hawker (1825) says:

“There are two ways of putting a ‘hammer’ (frizzen) in motion—one with a wheel in a feather spring, the other with a bridge there over which a wheel in the hammer is made to run. Durs Egg and Mr. Manton usually make the first; Mr. Joseph Manton the other. This is a good way of determining the maker of ‘Manton’ locks—only the Joseph Mantons being of great value to the collector; the other Manton—John Manton—was his rival and brother, and was once foreman to the celebrated Twigg.”

The pan in flint-locks is placed low down below the touchhole in order that the first flash of the priming fires the charge. In pieces where the touch-hole is at the bottom of the pan, the priming had all to burn away first, before the discharge occurred.

Flints should be put in flat side upwards, and held in a piece of leather. If they do not force the frizzen back while in this position, they may be reversed, which makes it strike lower. In the old days, flints were of special sizes, and had to be very carefully adjusted by packing more or less leather round them to give the best strike.